Expert Solutions Designed and Built for ISO-Class Environments

Cleanrooms require more than just clean conditions: they demand precision, control, and a commitment to minimizing contamination at a high standard. In industries where quality and safety are critical—such as biomedical device manufacturing or semiconductor manufacturing—the right technology and standards not only make a significant difference in production but also ensure all products and solutions meet the rigid specifications and safety requirements of end users. Evolution Motion Solutions delivers custom-engineered products and systems that meet strict ISO cleanroom classifications, supporting medical, pharmaceutical, and semiconductor industries with reliable, proven solutions.

Our products are built to perform in cleanroom environments where air purity, particle control, andelectrostatic safety are essential. From modular aluminum framing systems to linear motion modules, we provide cleanroom-ready solutions tailored to your specific application needs.

Custom Cleanroom Solutions

No two cleanrooms are alike, and neither are the systems that support them. At Evolution, we specialize in developing custom cleanroom solutions based on your ISO requirements. Our Motioneer team, a group of engineers dedicated to creating custom concept engineering solutions, collaborates directly with you to learn and understand your application requirements to craft a tailored solution for your cleanroom. From customized workstations to fully integrated automation solutions, we’re here to support you at every step of the design and engineering process, helping you conceptualize and develop cleanroom-ready solutions that align with your workflow and cleanliness requirements.

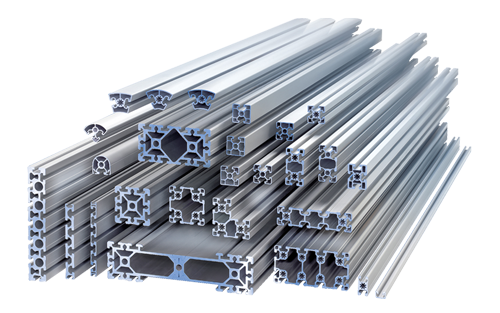

Aluminum Extrusion for Cleanroom Applications

Bosch Rexroth aluminum extrusion framing systems are designed to help maintain cleanroom integrity while offering the flexibility to customize structures specific to your system’s needs. These modular components support cleanliness through strategic design and material qualities, whether you’re designing workstations, flow racks, enclosures, or machine frames.

Each aluminum profile features dedicated channels that serve as pathways for wiring, cabling, conduit, and other sources that could attract dust or hold a static charge, leading to contamination in a cleanroom environment. By containing these elements within the extrusion itself, the risk of particle accumulation and electrostatic interference is significantly reduced, eliminating clutter that can compromise cleanliness.

Rexroth aluminum profiling is coated with an anodized finish to increase corrosion resistance, pairing well with the t-nut fastener, which can break through this coating to ensure a conductive connection in ESD-sensitive environments. Rexroth aluminum framing is easier to ground when electrically tying all struts together. T-nuts ensure strong, adjustable joints without introducing additional contaminants.

Customize your aluminum extrusion with Evolution’s Bosch Rexroth Aluminum Extrusion Stocking Program.

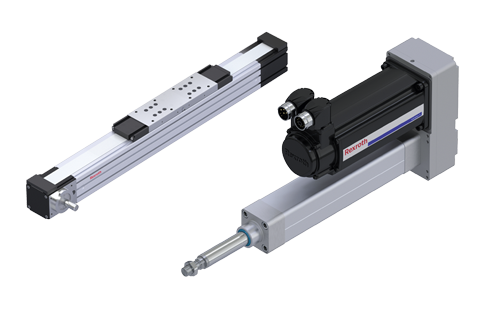

Cleanroom-Ready Linear Motion Technology

Multiple factors influence how a linear motion system performs in a cleanroom, including travel speed, acceleration, load, duty cycle, installation position, system geometry, thermal output, lubrication, and extraction. Bosch Rexroth’s EMC and MKR (PDF) linear slides account for all of these. Tested under real-world conditions by an accredited third party, these linear modules contribute to the reduction of particle emissions through purposeful material selection, optimized construction, and certified cleanroom operations—all without needing special configurations.

The EMC and MKR linear actuators feature corrosion-resistant materials, which help prevent particulate release over time due to wear or oxidation, and protective surface coatings as an alternative where full corrosion resistance isn’t possible. Rexroth’s standard lubricants, which are approved for cleanroom use, reduce friction without introducing excessive outgassing, ensuring clean and repeatable motion over the system’s lifetime.

These linear modules can be customized to improve performance and better suit specific cleanroom environments. Our engineering team can drill and tap vacuum lines directly into the housing, near motors or lubrication points, allowing airborne contaminants to be collected at the source before entering the surrounding air. This optional modification eliminates the need for separate containment systems and helps prevent outgassing materials from degrading your cleanroom.