Leantechnik has been a leading supplier of linear gear rack lift drives for automation systems for more than 30 years. Known for their synchronous, precise, fast, and reliable products, they maintain a consistently high standard of precision, speed, and reliability while ensuring flexibility. Their innovative solutions are applied across industries, including transportation technology, mechanical engineering and construction, food and chemical, and automotive sectors.

Leantechnik’s gear rack lift drives are designed for efficiency and effectiveness, making them suitable for any application requiring precise motion implementation. Their passion for movement and dedication to customer success drive them to continually push the boundaries of technology and performance.

By focusing on delivering high-quality, reliable, and innovative products, Leantechnik ensures that their customers achieve success in their automation projects. Their commitment to excellence and flexibility allows them to meet the diverse needs of various industries, making them a trusted name in linear motion technology.

With a focus on customer success, Leantechnik combines innovation with practicality to provide solutions that enhance the efficiency and reliability of automated systems. Their products are optimized for peak performance and tested to meet the highest standards, ensuring they operate safely and effectively.

A Complete Lifting System Solution

As an engineering partner, systems integrator, and value-added distributor (ESV), Evolution Motion Solutions is perfectly positioned to concept, design, engineer, source, and integrate a custom lift solution. Our access to products that are complementary to Leantechnik, such as linear guides and servo controls, allows our team to optimize a complete lifting system for your application. We also guarantee sizing accuracy, working alongside your team to get the specifics of your application and performance requirements. After evaluating the entire picture, our team will select the best components and system design to meet your needs, creating a comprehensive and tailored mechanical solution.

Customized Gearboxes

- Develop custom gearboxes to meet your specific application needs

- Extensive product knowledge and resources available

- Customizable solutions to meet requirements for particular loads, coating or material specifications, dimensions, or environmental durability.

- Coating options include burnished, galvanized, anodized, or Duralloy

- Stainless steel option available

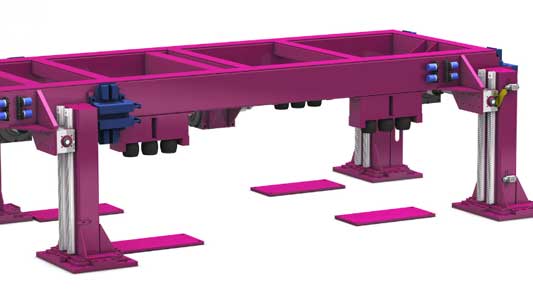

Lifting Systems

- Synchronous lifting systems

- Tailored to meet your parameters for length, space, speed, and capacity

- Ideal for lifting tables, lifting columns, or elevating conveyors

- Supports lifting tables for high loads with high positioning and repeat accuracy

- Can also be tailored for lifting high and decentralized loads or be used as an intermediate stacker

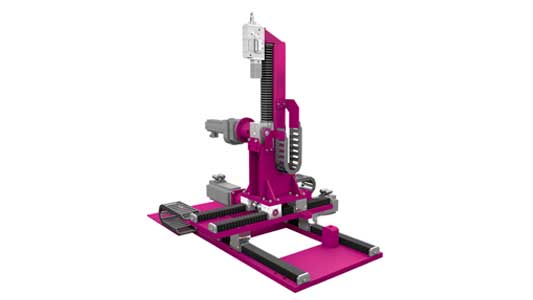

Flexible Positioning Systems

- Flexible and highly adaptable positioning system

- 2- or 3-axis positioning system

- As a vertical 2-axis positioning table, ideal for high payloads with fast travel speeds

- 2-axis solution provides the ultimate flexibility by offering a suspended version

- Designed to absorb transverse and process forces

- Suited for the automotive industry, where it can adapt to different pickup points for each car body

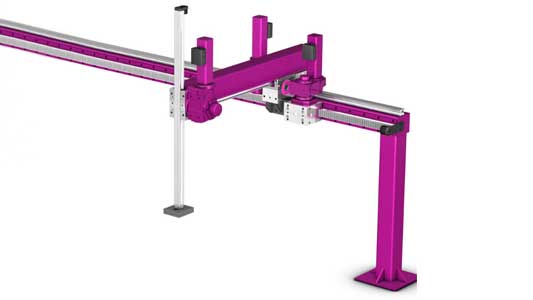

Shuttle-Systems

- Quickly transfer materials from one area to another with Leantechnik’s transfer and shuttle system

- Built for durability and speed

- Surprisingly compact

- Effectively transfers materials with various shuttle solutions. Whether a suspended 1-beam shuttle or a standing 2-axis transfer parts conveyor, Leantechnik can meet your material transfer requirements

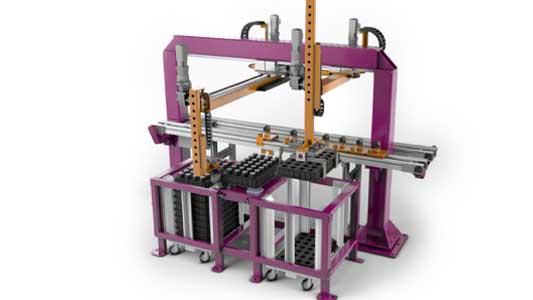

Pick-and-Place

- Durable pick-and-place system

- Move large loads quickly, precisely, and reliably

- Several system variations to meet your application needs: 2, 3, or 4-axis solutions

- Variable 2-axis gantry is flexible with the ability to attach grippers, clamps, vacuum devices, or additional devices to the ends of the rack

- 3-axis system is compact with an extendable support arm, making it ideal for single-sided access

- 4-axis system is suited for picking up surface-optimized cut parts and stacking them congruently on opposite pallets

Complete Systems

- An adaptable complete gantry system utilizing Leantechnik’s gearbox technology and accessories

- Application examples:

- Complex sorting systems for logistics

- Transferring parts in and out of chemical baths

- Combined 2-axis palletizer and feeder solution with gripper jaws attached to the gearbox rack

Product Offerings

Power Transmission

- Servo Rack & Pinion