Bosch Rexroth has years of conveyor manufacturing experience and a long track record of developing durable products with innovative technology. Their conveyor solutions are used in the automotive, electrical, and appliance industries for production, assembly, and testing tasks. The conveyor solutions can support a broad range of products weighing from a few grams to 400 kg. Bosch Rexroth conveyors fall into two main categories: pallet-based and plastic chain. Their pallet-based conveyors, like the TS2plus, are non-synchronous and built to enhance manufacturing productivity. For a quieter solution, manufacturers can select a plastic chain conveyor option such as the VarioFlow Plus. Both conveyor options have modular designs to allow for future flexibility and adaptations to your manufacturing process.

Conveyor Selection and Sizing Support

As an Engineering Partner, Systems Integrator, and Value-Added Distributor, Evolution can assist with selecting and sizing your conveyor solution. Our team utilizes extensive industry and product knowledge to develop optimized solutions for our customers based on their performance needs. The Evolution team can also help with integrated or offline workstations and the accompanying tools. We also provide complete system drawings, and all of the system components are delivered in clearly labeled bags for easier assembly.

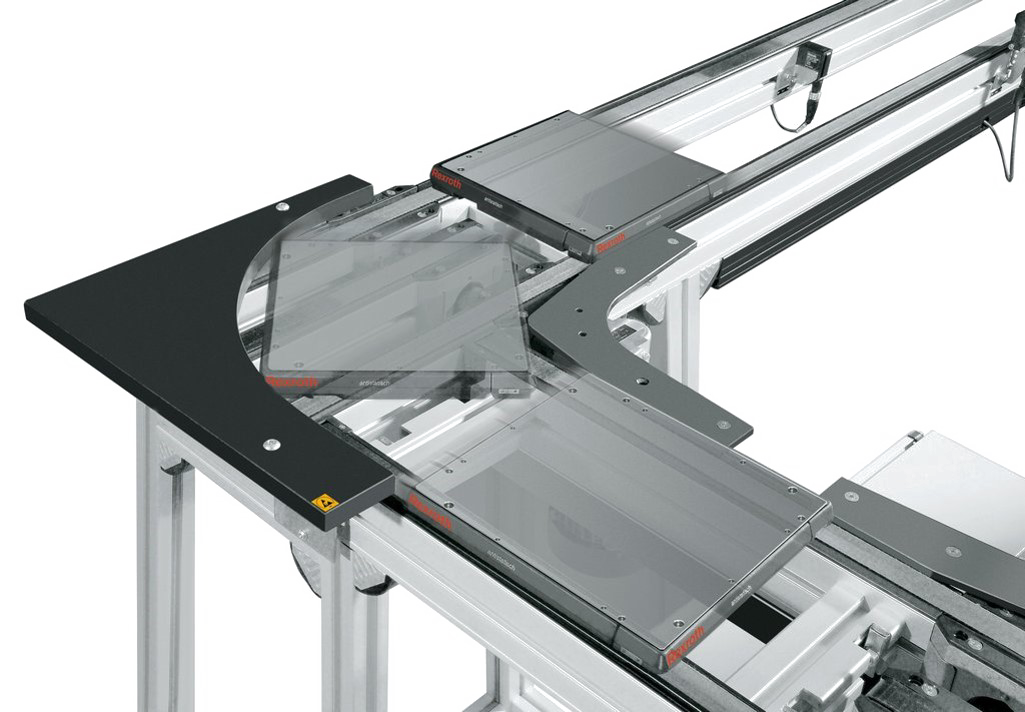

TS 1 Conveyor System

TS 1 Features

- Space-saving, cost-efficient solution for small, lightweight products

- High precision

- Suitable for special environmental requirements such as clean rooms and ESD conditions

- Easy to use thanks to clear, modular structure

- Standardized components

TS 1 Application Examples

- Small electronic components

- Automotive components like sensors and coils

- Biomedical components

TS 1 Sizes and Weight Capacities

- Size 1: 80 x 80 mm, 1.5 kg

- Size 2: 120 x 120 mm, 2.2 kg

- Size 3: 160 x 160 mm, 3.0 kg

TS 1 Speed Range

- 9, 12, 15, or 18 meters per minute

TS 2plus Conveyor System

TS 2plus Features

- Robust, economical solution for mid-load range

- Suitable for special environmental requirements such as clean rooms and ESD conditions

- Supports a wide range of products with various sizes and weights

- Modularity allows for future expansions

- Easy to use thanks to clear, modular structure

- High Precision

- Media Options: belt, toothed belt, flat top chain, roller chain

TS 2plus Application Examples

- Automotive components

- Pharmaceuticals

- Food and Packaging

TS 2plus Sizes and Weight Capacities

- Workpiece pallet size: 160 x 160 mm minimum – 1200 x 1200 mm maximum

- Workpiece pallet total weight: 240 kg

- Total section weight: 1800 kg

TS 2plus Speed Range

- 6, 9, 12, 15, or 18 meters per minute

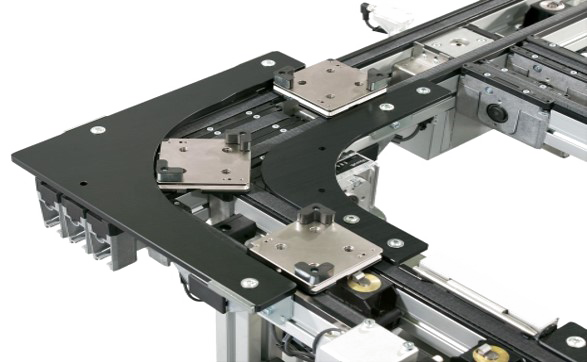

TS 4plus Conveyor System

TS 4plus Features

- Robust system for high loads up to 2 kg/cm

- Reliable conveyor system with minimal downtime

- Easy mounting for quick installation

- Simple and cost-effective maintenance

- Variable length, width, and speed

- Media: #60 roller chain

TS 4plus Application Examples

- Automotive components

- Household appliances

- Large electronics

- Large, heavy products

TS 4plus Sizes and Weight Capacities

- Workpiece pallet size: 443 x 443 mm minimum – 1243 x 1243 mm

- Workpiece pallet total weight: 250 kg

- Total section weight: 2500 kg

TS 4plus Speed Range

- 6, 9, 12, 15, or 18 meters per minute

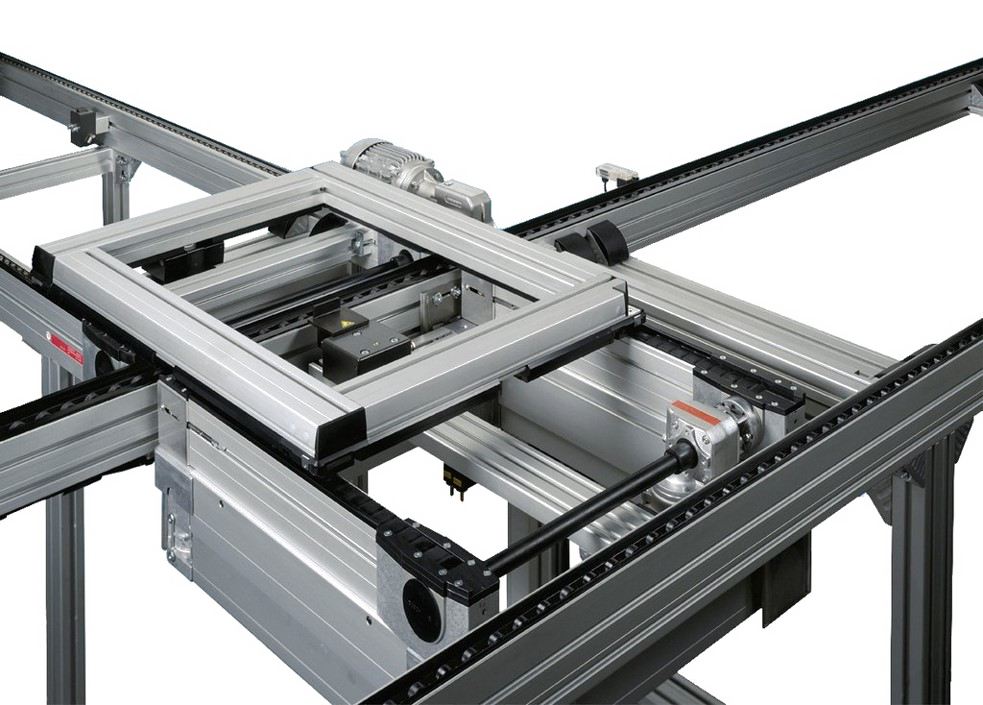

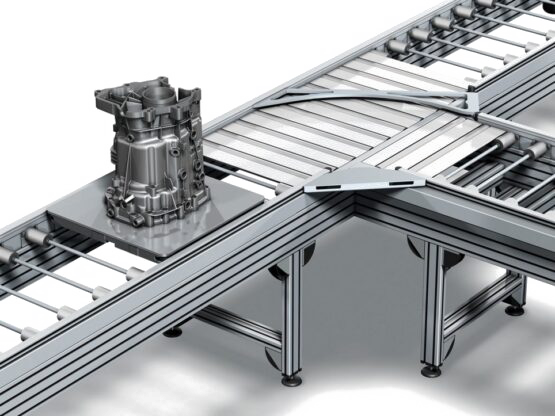

TS 5 Conveyor System

TS 5 Features

- Maintenance-free roller conveyor for harsh production environments

- Efficient production through planning and commissioning process

- Adjust the friction for each roller from the outside without a tool

- Modular system with defined interfaces

- Easily integrate a 3-way diverter, rotator unit, front end drive, and a compact stop gate into the final system

- Tandem transportability for extremely long products

- Media: powered roller with zinc or nitrile finish

TS 5 Application Examples

- Automotive components like powertrains

- Large appliances

- Large, heavy products

TS 5 Sizes and Weight Capacities

- Workpiece pallet size: 455 x 455 mm minimum – 845 x 1040 maximum

- Workpiece pallet total weight: 400 kg

TS 5 Speed Range

- 2 to 18 meters per minute

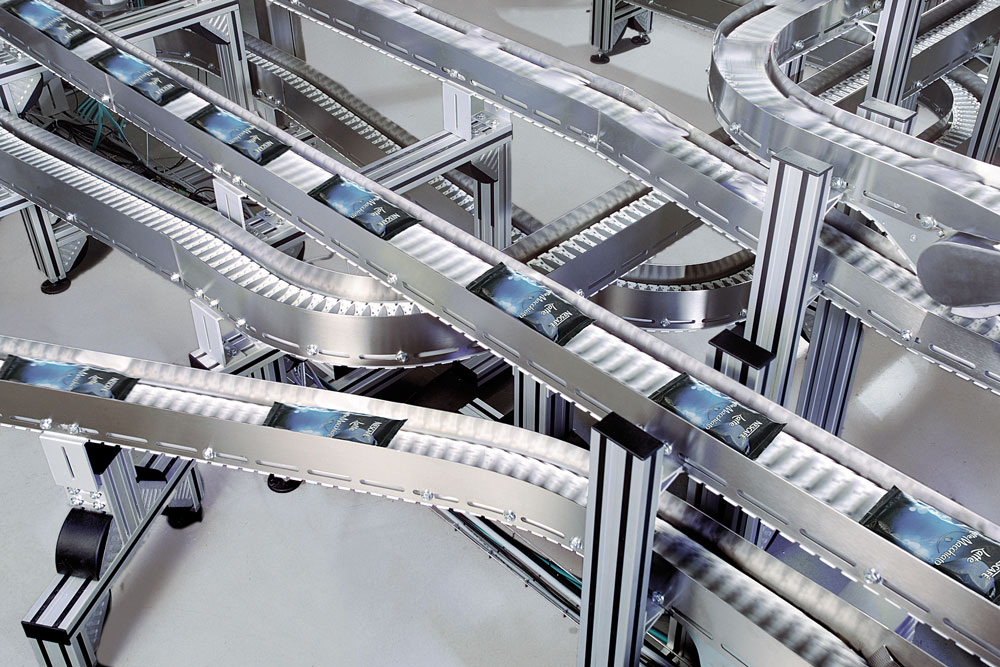

VarioFlow plus Conveyor System

VarioFlow plus Features

- Improved energy efficiency due to lack of friction

- Longer product lifetime

- Up to 10% lower noise emissions

- Easier to clean and maintain FDA compliance

- Easy assembly and more mounting options

VarioFlow plus Application Examples

- Machine linking

- Packaged goods transportation

- Filling, capping, and labeling line

- Product accumulation and buffering

VarioFlow plus Sizes

- 65, 90, and 120 use closed conveyor profiles and curve wheels

- 160, 240, and 320 use open conveyor profiles and roller wheels

TS 2plus Speed Range

- Up to 60 meters per minute (up to 100 m/min available upon request)