Numerous industries and applications require moving very heavy loads or transporting loads at high speeds. Many people have tried to engineer solutions using multiple products from numerous manufacturers to develop their own linear system that can move the heaviest loads at the desired speed. But this process requires extensive complex engineering and an incredible amount of time to develop, which can sometimes open up room for expensive errors. Even the most experienced engineers can make mistakes, especially when it comes to challenging system designs like one, two, or three-axis linear motion systems.

Instead of designing and creating linear motion slides from scratch, what if you could submit your desired specifications and then have your custom linear slide design ready for you after only a short waiting period? Why not reduce the stress and hassle of independently engineering linear motion slides and instead lean on a team with extensive experience?

Engineered Linear Modules are systems that utilize an in-house, at-the-ready engineering team prepared with tried and true linear system designs specifically for heavy loads and/or high speeds. These designs can be adapted to your requirements and specifications – all you need to do is provide specifications for load, orientation, speed, travel, precision, environment, and duty, and we take it from there. Reduce room for error, work with linear motion specialists, obtain a final design, and rest easy.

Applications & Industries

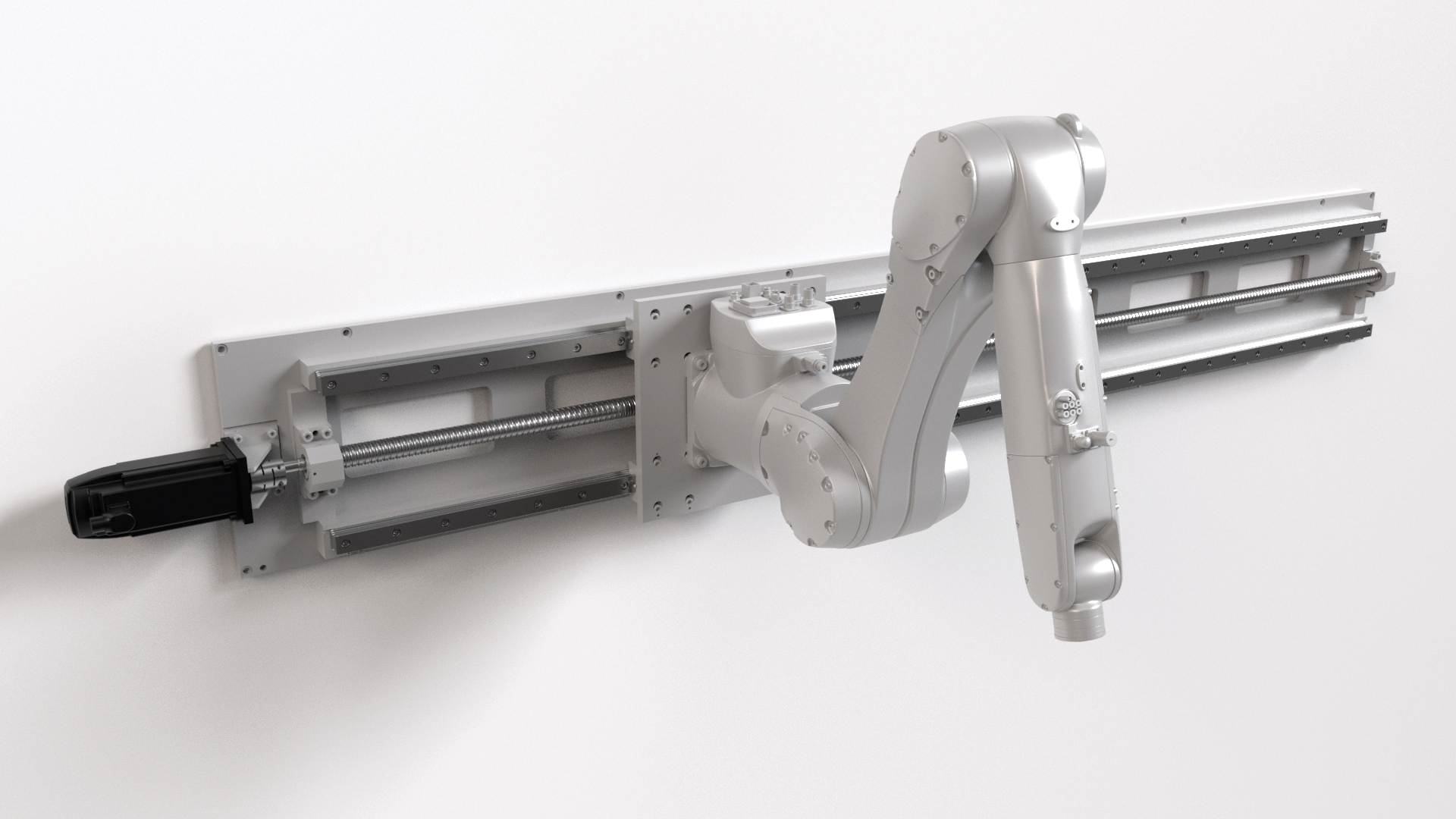

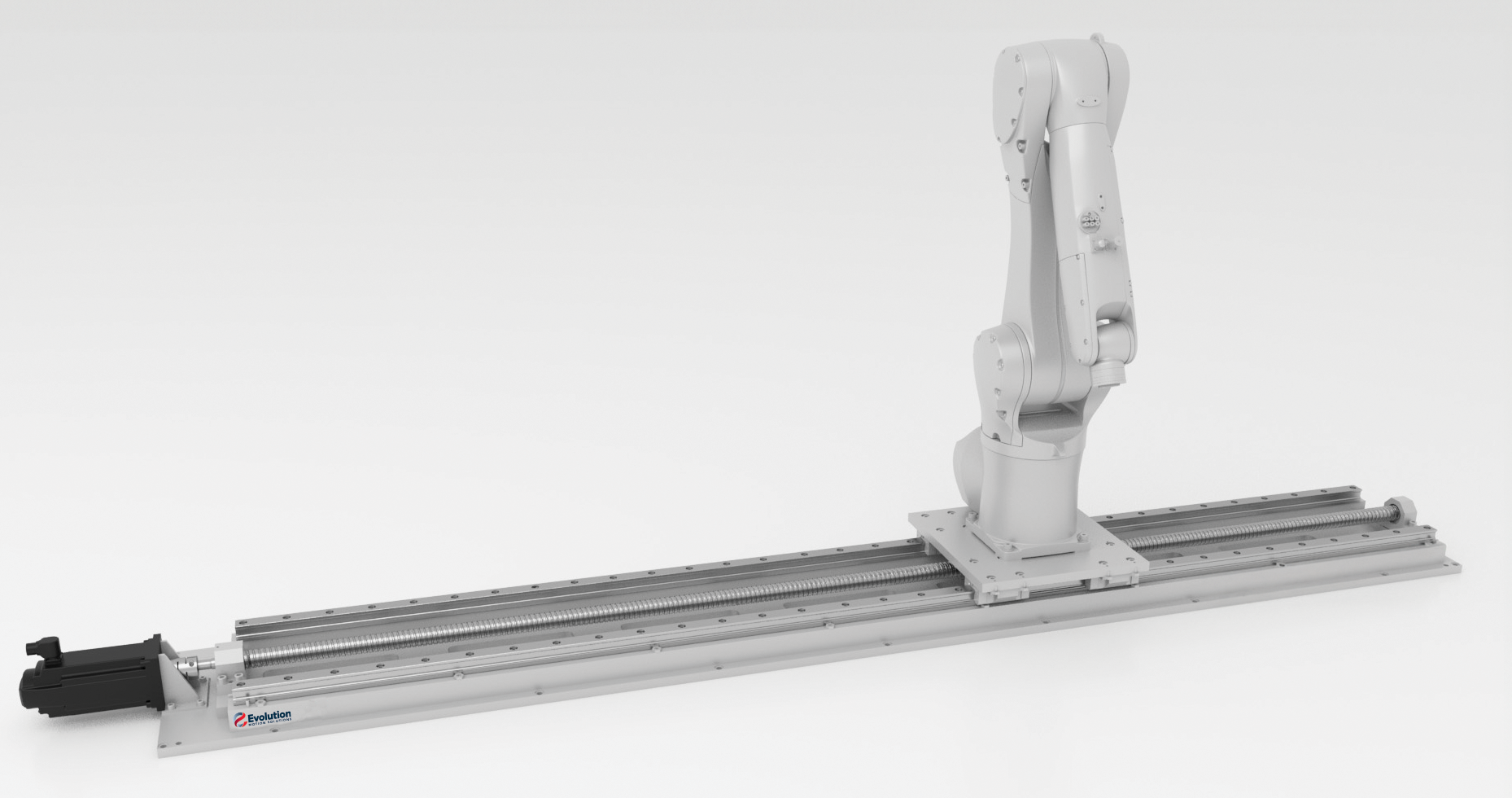

Using only the most durable and highest quality components designed for heavy loads and/or high speeds, including best-fit runner blocks, Engineered Linear Modules easily integrate into many applications, such as robot transfer units (RTUs), electric battery manufacturing, and gantry systems. RTUs enable robots to perform tasks over a larger area or work multiple stations without needing multiple tools. By incorporating Engineered Linear Modules and their heavy load/high-speed capabilities, RTUs can obtain higher levels of power not attainable with standard modules on the market, allowing them to become more efficient and productive. With their versatility, these modules are ideal for quickly transporting fast-moving consumer goods (FMCGs), raw materials, and industrial components – making them a valuable asset for many industries.

Drive Options

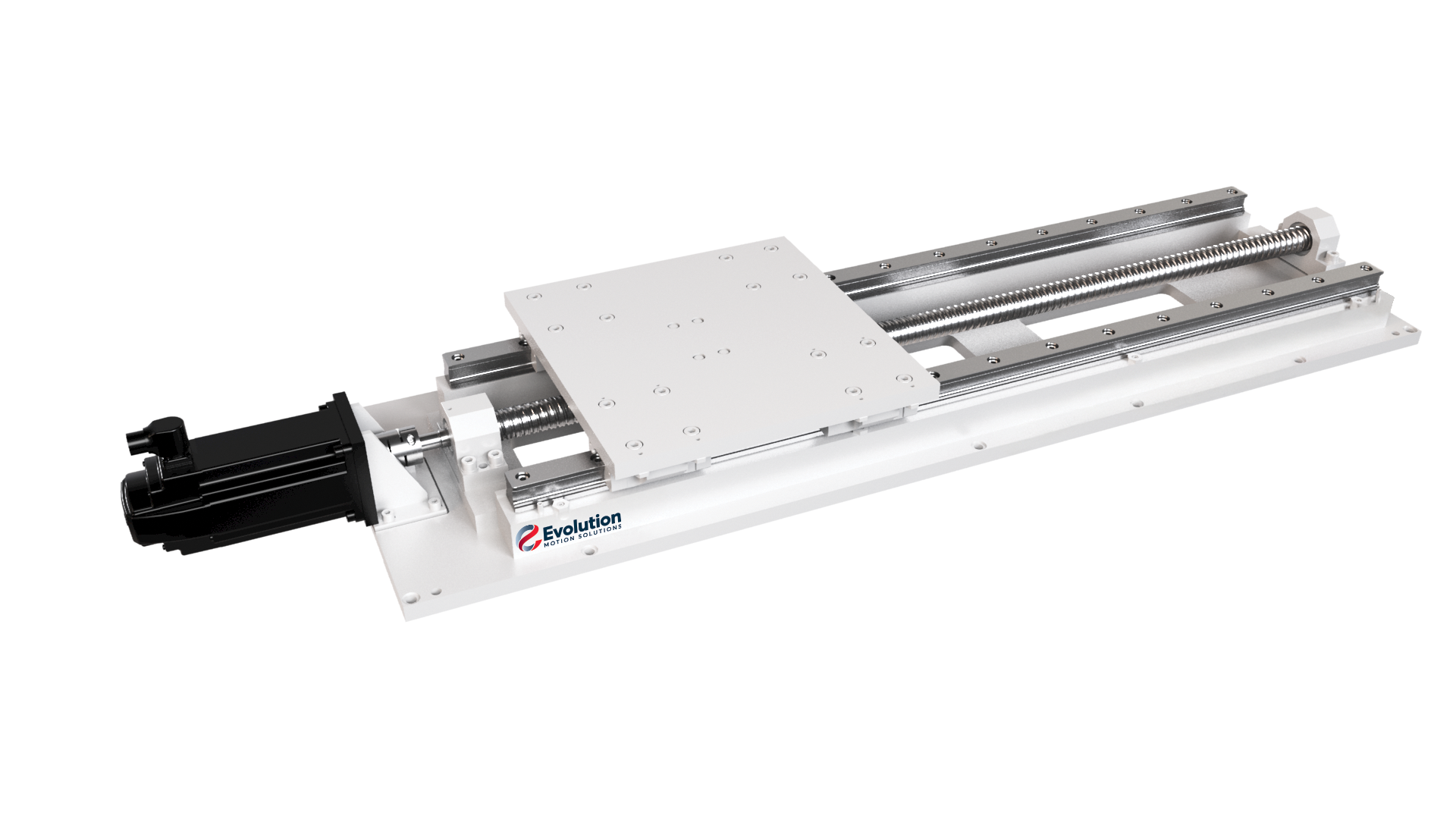

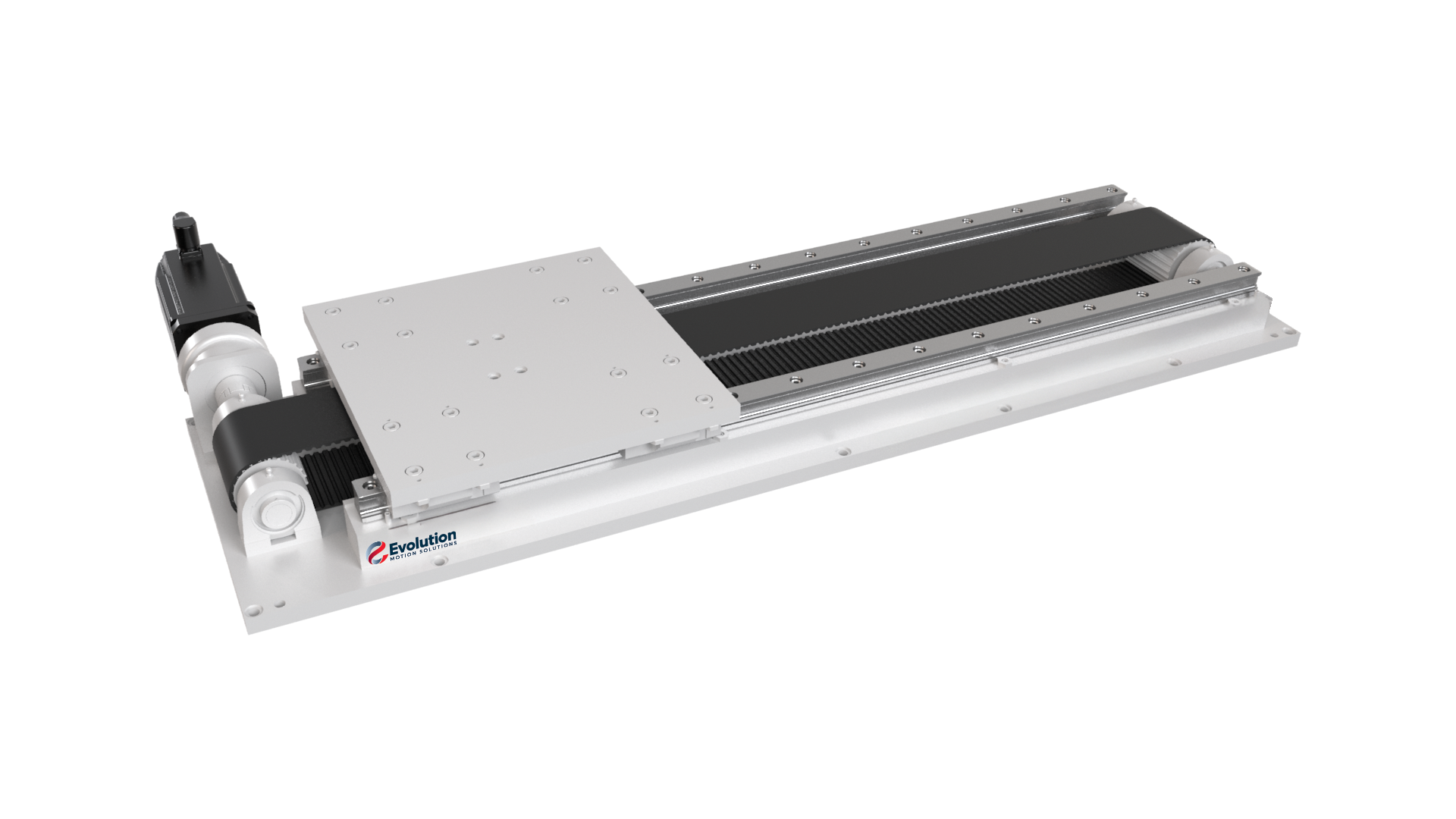

Engineered Linear Modules have different drive options: ball screw, rack and pinion, and belt drives. It’s essential to consider accuracy, repeatability, speed, and acceleration, as these modules provide different levels of performance. Ball screws generally have higher accuracy than rack and pinion and belt drives. If speed is a priority, a belt drive may be the optimal choice as it typically provides the fastest performance. Rack and pinion drives are better suited for heavier loads and longer travel distances than ball screws and belt drives.

Ball Screw

Rack & Pinion

Belt Drive

Configurations

Your system’s construction, intended use, and mounting configuration also affect which drive option best fits your application. For example, a system may be mounted to a plate on the floor, on a steel weldment, or on an aluminum structure, and that mounting may be placed on the floor, wall, or ceiling. By providing your system’s configuration, specifications, and requirements for accuracy, repeatability, speed, and acceleration, we can choose the best-fit drive option for your customized Engineered Linear Module.

Want to private label our Engineered Linear Modules as your own? Ask us about our white-label option!

Resources

Sell Sheet

Factory Automation Brochure

RTUs vs CTUs

The Complexities of Engineering Linear Modules

Discuss Your Project With An Expert

To learn more about our suppliers or ask our team any questions you might have, contact us today.