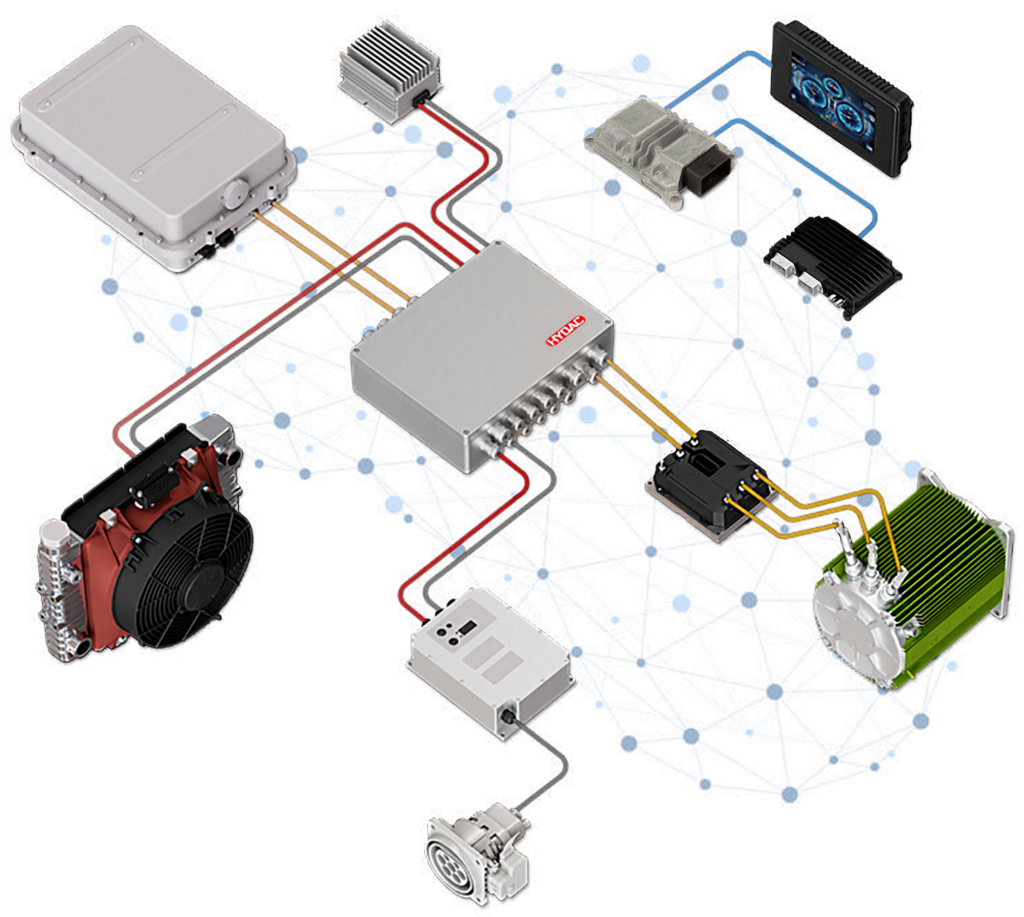

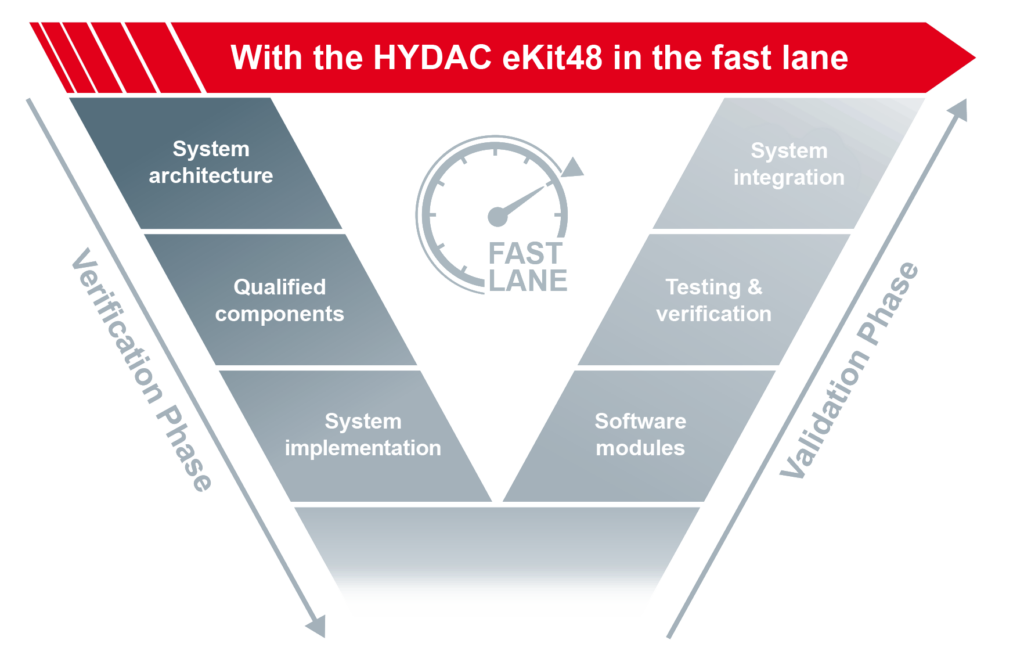

Electrification processes often demand significant time and resources, particularly in designing individual system packages where each component needs thorough testing and evaluation. In the realm of mobile electrification, innovative solutions must be implemented swiftly to achieve progress in environmental protection and emission-free technologies. To help OEMs create electrified machines sooner is HYDAC’s revolutionary 48 V system eKit48. This system features pre-validated modules for custom configuration, easily integrating into existing architectures with intelligent configuration strategies. The eKit48 offers a comprehensive, innovative package that simplifies the transition from conventional combustion engines to electrified machinery, ensuring quick implementation, emission-free technologies, and enhanced system efficiency.

- Simple and user-friendly operation

- No training needed

- Maximum flexibility with a standardized, modular design

- Easily adapts and integrates into any system architecture

- Readily available and highly compatible components

- All components developed and produced in-house at HYDAC and HYDAC subsidiaries and partners, including Engiro, Invenox, and TTControl

- Concentrated know-how and dedicated support

Experienced Guidance

As an engineering partner, systems integrator, and value-added distributor (ESV), Evolution Motion Solutions is here to support you at every step of the electrification process. We work closely with you to learn and understand your machines so we can provide the best possible solutions and support tailored to your specific needs. Whether you need guidance on how to electrify, programming support for the eKit48, or engineering resources throughout the electrification process, our expert engineers and technicians are available to help you succeed.

eKit48 Modules

Power Distribution Unit

All components connect to the power distribution unit (PDU), which distributes energy safely and efficiently. Designed to match the dimensions of other elements in the kit, the PDU provides optimum power distribution with standard or customized harnesses.

Technical Data

- Mini PDU

- 1 motor and up to 2 batteries

- 230 x 330 x 110 mm (9.05 x 12.99 x 4.33 inches)

- Maxi PDU

- 2 motors and up to 4 batteries

- 310 x 400 x 110 mm (12.20 x 15.75 x 4.33 inches)

- Continuous load: 500 A, short-term up to 1,000 A

- Standardized interfaces to the cable harness with individually fused current paths

LIOS 48 Battery Systems

HYDAC’s innovative and intelligent battery systems from the Invenox Division use patented contact technology to clamp cells between aluminum PCBs. Elastic and highly conductive materials ensure vibration-resistant contact, while pole contact cooling dissipates heat effectively. The battery management system provides dual-level monitoring for maximum failure protection. Defective battery cells are easy to replace, and modules are recyclable thanks to reversible clamp detection.

Technical Data

- Power for especially powerful performance: LIOS 48S P (60 Ah / 3 kWh) or LIOS 48L P (90 Ah / 4,5 kWh)

- Energy for an especially long service life: LIOS 48S E (80 Ah / 4 kWh) or LIOS 48L E (120 Ah / 6,1 kWh)

- Dimensions: 398 to 511 x 370 x 176 mm (15.67 to 20.12 x 14.57 x 6.93 inches)

- 28 to 40 kg (61.73 to 88.18 lbs) depending on the variant

- Cycle stability: > 3,000

- Certifications: IP-6k7, UN38.3, ECE R-10, CE declaration

Charging Management

Preconfigured modules align with the Low Voltage Directive and EMC guidelines, covering power ranges from 1.5 to 12 kW and compatible with supply voltages from 100 to 240 Vac. This technology ensures safe and efficient charging processes equipped with an ECSE controller, CAN interface, and EVSE-compatible communication interfaces (SAE-J1772 and EN-61851-1).

Technical Data

- Up to 3.3 kW charging power per device, parallel operation of 2 devices is possible

- Working temperature: -20 °C to +70 °C (full performance up to 50 °C)

- Certification: CE / cUL / IP65 / UNECE R10

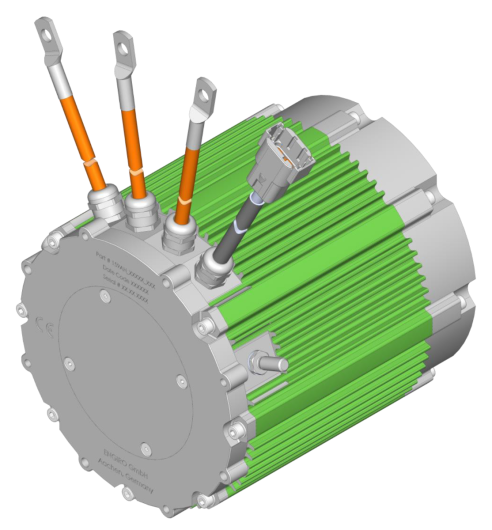

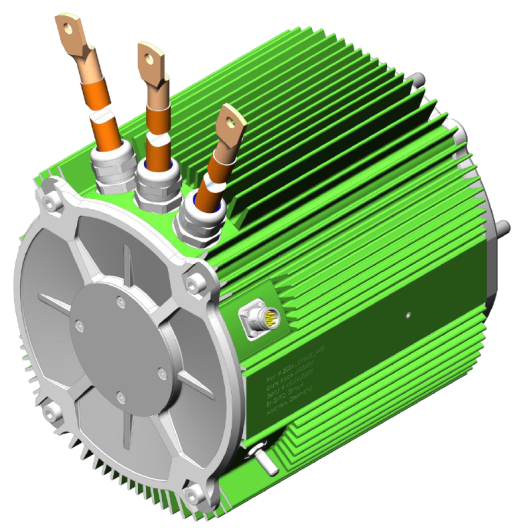

Drive Sets

Turnkey drive sets from the Engiro Division consist of a motor, a coordinated converter, and a matching cable harness, all tested and parameterized on HYDAC’s drive test benches. These sets in the eKit48 are ready for immediate use and suited for applications requiring high speeds and torques as well as various flange and shaft types.

Technical Data

- Drive speeds up to 8,000 rpm & torque up to 200 Nm

- Protection class: IP 65 n Certifications: CE, EN 60034

Mobile, Variable-Speed Air Coolers

The AC-M air cooler provides needs-based cooling for electric motors and inverters with minimal energy loss. Its compact, variable-speed design ensures it only uses as much energy as needed. Cooling based on application needs helps reduce noise and vibrations.

Technical Data

- Protection class IP68 (IP6K9K on the whole fan)

- Compatible with various oil types as well as water glycol mixtures

- Axial fan in suction or blowing version

Software

MATCH control software for mobile machines from the TT Control Division consists of certified and tested function modules for custom combinations to ensure quick and safe implementation. This software and the communication cable harness offer 12 or 24 V interfaces for customization and reliable system communication.

Technical Data

- Exchangeable and expandable function module

- Multi-controller capable

- With a standard or custom cable harness

Controllers

Robustly designed controllers ensure the eKit48’s smooth and efficient operation in harsh mobile/off-highway conditions. With numerous safety certificates and up to seven CAN bus connections, these controllers provide maximum flexibility and code reusability across all products.

Technical Data

- Operating temperature -40 °C to +85 °C

- Infineon XC 22xx micro controller, 80 MHz, 768 kB int. Flash, 82 kByte int. RAM 8 kByte EEPROM

- Certifications: ISO 26262 / EN INO 13849 / ISO 25119 / ISO 19014