In semi-trailer manufacturing, repeatable and precise rivet mashing is not just a requirement but a foundation for quality and durability. Traditional riveting is a manual process, and while commonly accepted as the standard process, it leaves significant room for error in tolerance because consistent and exact precision can be challenging to achieve with a human hand. Inconsistent and imprecise rivet tolerance can cause weak joints, increased stress concentrations, and poor airtight seals. Additionally, these manual rivet mashing processes utilize hydraulic power units that create workplace safety hazards due to long hoses strung across the floor and higher-than-necessary energy costs.

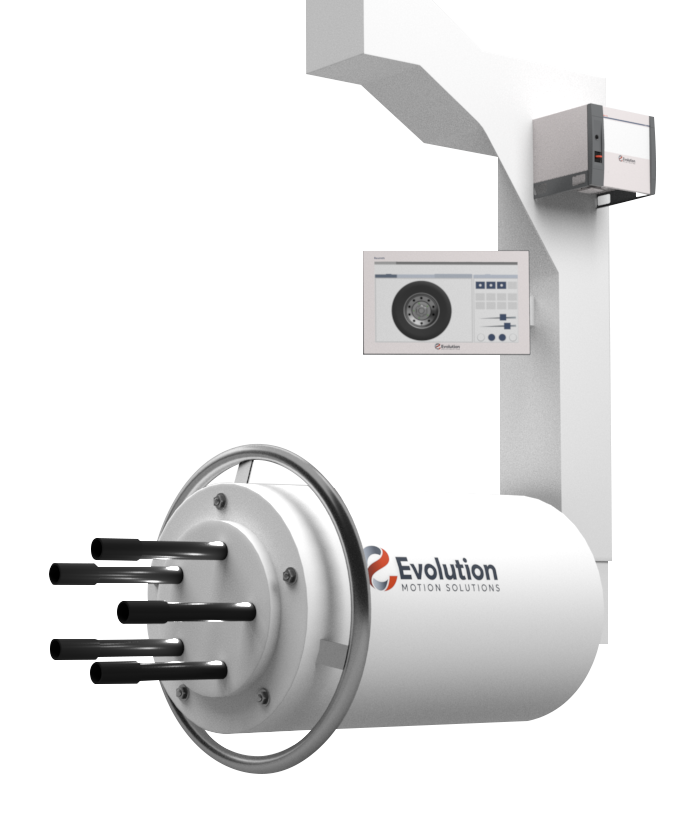

The Automated Riveting System is a game changer in semi-trailer manufacturing because it takes advantage of Sytronix, a seamless blend of hydraulics and servo drives, to intelligently match the motor’s speed to the machine’s demands, resulting in unmatched precise, repeatable rivet mashing.

How It Works

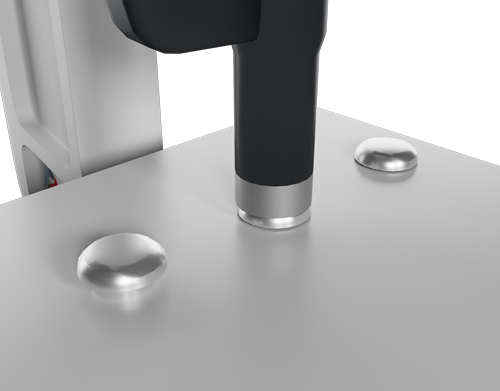

A metal sheet starts its journey on a conveyor, where a punch press creates all the holes for riveting. As the panel moves along, rivets are placed into every hole. Then, the spotlight turns to the rivet mashing tool powered by Bosch Rexroth Sytronix. An automated process moves the tool to each rivet in the metal sheet and precisely mashes each rivet to the correct tolerance. When full performance isn’t needed, the system smartly adjusts the pump’s drive, reducing speed or pausing, to save energy. This cuts energy consumption and reduces noise, making the workplace more efficient and comfortable.

Sytronix units are smaller than traditional HPUs, allowing the Automated Riveting System to be contained within a single rolling cart. This compact design removes the hazard of long hoses strung across the floor while improving the system’s mobility and efficiency. Sytronix units also significantly decrease energy usage as the system smartly adjusts the pump’s drive, reducing speed or pausing to save energy. With Sytronix, the Automated Riveting System provides highly precise, repeatable rivet mashing for semi-trailers.

Automated Lubrication System

The Automated Lubrication System pairs perfectly with the Automated Riveting System. This system also helps reduce incident and warranty claims by correctly tightening every trailer lug nut to the proper torque. Invest in the Automated Riveting System and the Automatic Tightening System and protect your company’s future.

Automated Tightening System

The Automated Tightening System pairs perfectly with the Automated Riveting System. This system also helps to reduce incident and warranty claims by properly lubricating trailer wheel axles. Invest in the Automated Riveting System and the Automatic Tightening System and protect your company’s future.