Repair, Reman, and Retrofit

Whether your IndraDrive components are newly installed or reaching legacy status, Bosch Rexroth offers a full suite of services to keep your systems performing reliably, efficiently, and safely, backed by over 200 years of combined Rexroth product repair experience in the USA.

Services Benefits

- Increased machine availability

- Production reliability through planned downtime

- Reduction in lost production costs

- Predictable budget with fixed prices

- Safe, no emergency cases

- Extension of machine and product life

- Investment protection

Certifications

- ISO

- UL

- ATEX

- Soldering IPC-7711, IPC-A-610

Repair

Our factory-authorized repair services restore your IndraDrive units to full function when issues arise. Each repair includes comprehensive diagnostics, cleaning, part replacement, firmware updates, and complete end-of-line testing. The repair report includes inspection, testing, the customer’s stated problem, and potential failure analysis. Repairs are backed by a 12-month warranty and performed by certified Bosch Rexroth technicians using original components.

Reman Plus

Restore to like-new performance and save on replacement costs with Bosch Rexroth Reman Plus services. Your drive is disassembled, refurbished, and rebuilt to factory specifications, replacing all failed and worn components to like-new condition, correcting any problems, and updating to the latest technical revision. Reman Plus services provide a 2-year warranty, an extension of 5 years serviceability, and dedicated storage of repair materials, ensuring the repair of equipment beyond the end of service. Remanufacturing with Rexroth is a cost-effective, sustainable alternative to replacement that extends machine life.

Retrofit

When your IndraDrive units reach the end of their lifecycle, retrofitting provides a path forward. Bosch Rexroth helps you migrate to newer technologies with minimal design changes and maximum compatibility. We support you through every step, from product selection to on-site commissioning.

What Sets Us Apart from Third-Party Repairs?

Backed by an extensive history and experience in servicing and repairing, Rexroth provides higher-quality repairs than third parties, preserving the original component integrity.

- Only original factory OEM parts

- Original factory-trained techs

- Original specifications

- Factory-certified testing/calibration

- Technical product updates for continuous product improvement

- Less than 1% of warranty claims on repairs

- Total cost of ownership advantage

- Failure history/fault trend analysis

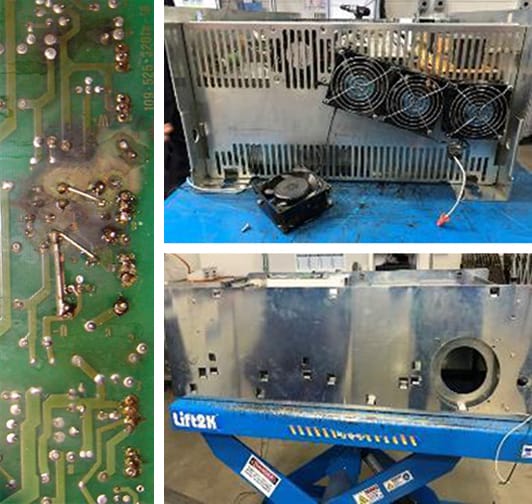

Third-Party Repair Attempts

PROBLEM: Damaged shaft seal ring has not been exchanged

RESULT: Shaft seal ring will wear much faster

PROBLEM: No heat-conducting paste at the commutator

RESULT: Early failure of the unit caused by overheating of commutator

PROBLEM: Worn motor shaft was not repaired or replaced

RESULT: Shaft seal ring will wear much faster

PROBLEM: Capacitor soldered on the old pins, not fixed to board

RESULT: Not resistant to vibrations. May result in lost connection – failure

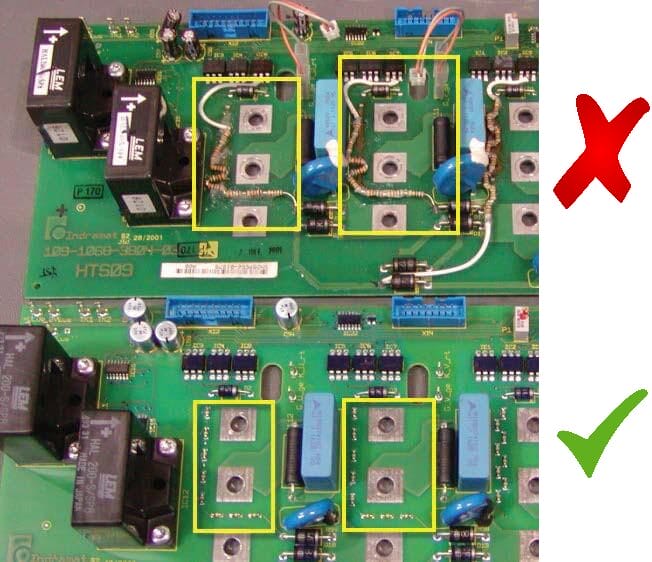

Third-Party Repairs – The Difference

Attempted 3rd party trace repair has damaged the PC card

- Multilayered boards cannot be repaired this way, due to multiple layers of traces

Incorrectly placed fans

- Fans are attached externally, which will not help cool the unit

- Unit with missing fan

3rd Party Attempt

- Used through-hole resistors and jumper wire instead of surface mount

Bosch Rexroth Repair

- Replacement board with correct surface mount resistors

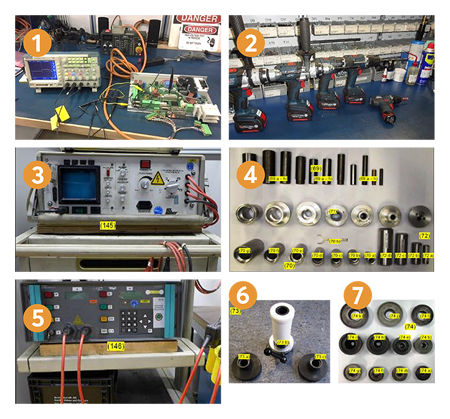

Motor Repair Tools and Technology

1 – Oscilloscope Calibrations (Electronic Repair)

2 – Bosch Rexroth Torque Drills

3 – Oscilloscope Calibrations (Motor Repair)

4 – Rear Bearing Installation Tool

5 – High Voltage Tester (HI-POT & Insulation)

6 – Brake Gapping Tool

7 – Wickedly Awesome Front Bearing Installation Tool

Training

End User

- Formal Classroom Training (On-Site & In-House)

- Traditional classroom environment with demos, manuals, and hands-on exercises to deliver course content

Shop Floor Training

- Senior service engineer will deliver the training on the shop floor utilizing the customer’s machine.

E-Learning

Web-based training offered in two formats:

Pre-Recorded Modules (Available 24/7)

- Instructor guided pre-recorded presentations that students complete at their own pace

Live Interactive Sessions

- Remote training sessions with access to both the demos and the instructor for a live, interactive experience

Formal Classroom Training

- Training sessions held in a traditional classroom environment. The instructor will utilize demos, manuals and hands-on exercises to deliver course content

- In-house: Hoffman Estates, IL, and other remote offices

- On-site: At customer location or secondary site designated by customer. On-site courses are available upon request and instructor availability

Online Training

Live Interactive Sessions

- Students may attend the training sessions remotely, gaining access to both the demos and the instructor for a live interactive experience. These courses are conducted in two 3-hour sessions per day. (8:30 – 11:30AM and 1:00-4:00PM)

Resources

Sell Sheet

Factory Automation Brochure

Factory Automation NE Line Card

Factory Automation Midwest Line Card

Factory Automation NTX, STX, SE, MT, Central Line Card

Keeping IndraDrive in Motion

Tony Little announces the status of IndraDrive and introduces dedicated servicing options.