Aggressive ferrous debris tends to contaminate industrial fluids, damage inline fluid systems and degrade fluid filter products. Magnom offers a unique solution to this issue with its magnetic filters.

Employing a unique core technology, Magnom Magnetic Filters clean micron and submicron-sized ferrous particles from a wide range of fluids.

Achieve Oil Cleanliness by Filtering out Ferrous Materials

Arguably, oil cleanliness is the most important feature in any fluid system. And the most dangerous threat to that cleanliness? Microscopic particles of ferrous materials (iron and steel).

Typically the hardest, sharpest, and smallest contaminant threat in a system, such particles cause leaks and dimensional changes. They reduce a system’s efficiency. And because they tend lodge in dynamic clearances and agglomerate, the chain reaction of wear they cause leads to sudden and catastrophic system failures.

You’ll find this to be especially true in closed loop lubrication and fluid power systems — hydraulics, engines, pumps, and transmissions, and so on. Over a long period of time, even a small amount of contaminant can destroy various components and areas of the system.

Open systems, too, are vulnerable to ferrous particles and the damage they can cause. Systems such as industrial processing, machine tooling, and product washing require daily inspection and, when necessary, removal of the huge amounts of debris that can accumulate. If not, the impurities can both cause significant damage to the final products and be transferred to other processes.

Complicating the situation, these “high risk” contaminants are invisible to the naked eye. Also, not all of the size ranges of contamination that threaten systems fall within ISO oil cleanliness standards. Finally, you are likely to learn — hopefully not the hard way — that on their own, traditional barrier filtration methods will not provide sufficient protection.

So, to enhance the lifetimes of and reduce downtimes with your inline fluid systems, it is essential to remove the fine ferrous debris down to submicron levels. This is becoming increasingly more important as more systems utilize close tolerance VP pumps and immersed circuitry. Also, we’ve seen the threat of contamination increase significantly with the reduction of system dynamic clearances.

Now, you have probably found out that a reliance on barrier filtration methods or compliance to ISO cleanliness standards offers limited protection against ferrous particle contamination. Also, the very real possibility is that the manufacturers of your inline fluid systems might not have put in much careful thought to the preventing these fine ferrous particles from entering your systems.

Where does the contamination come from?

Inbuilt — Sad to say, but the actual build process of individual inline fluid systems can result in a lot of contamination. From manufacture and machining to threading and cutting, each step leaves some ferrous debris.

Break In — In new systems, additional ferrous debris is produced and distributed throughout new machines as the components engage with each other.

Imported — Some contamination can just “find” its way into a system. Poorly sealed units, the rusting process, even the addition of new oil are all possible sources of additional ferrous particles.

Generated — The more a machine/system operates, the more contaminants it generates. Couple these with any existing inbuilt or imported impurities, and the potential to create even more ferrous debris exists.

The Solution: Magnetic Filtration from Magnom

The moving parts in fluid systems — such as bearings, gears dynamic seals, valves and pumps — typically have tolerances that range from 0.2 to 5 microns.

Magnom’s Magnetic Filters can trap particles down to 0.1 micron.

This unsurpassed ability to remove such microscopic ferrous particles from nearly any location in inline fluid systems makes Magnom’s patented fluid filter products ideal for all critical particle size ranges. Since its pressure drop across the filter is negligible, the core design can be used on the suction side of PD-sensitive components.

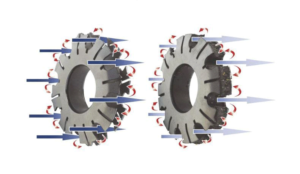

The marvel of Magnom’s patented core design is its simplicity, which uses only two components: an intense magnetic flux field gradient that cleans fluids of ferrous particles and two metal lens plates on both sides of each magnetic core assembly that enhance both the strength and the actual shape of this field.

The plates break up the flow of fluid through the core into very specifically designed V-shaped flow channels cut into their circumferences. The channels direct even the smallest particles within the range of the magnetic forces where they are pulled into the collection zone out of the flow path. Once collected, the particles remain in the core and are not reintroduced to the fluid during any pulsation of the flow. The channels exceed the feed pipe diameter; thus fluid flow is not impeded. As a result, there is never a risk of loss of flow through Magnom Magnetic Filter cores.

Unlike what frequently happens with other magnetic filtering devices, Magnom Magnetic Filters capture magnetic contaminants in the space between the plates where they remain without the risk of washing off. As a result, the fluid flows unabated while getting cleansed at the same time — just the ticket for effective cleaning!

The diameters of the magnetic filter cores are designed to maintain the optimum flow conditions in inline fluid systems. Typically, the cores are stacked on a central mandrel and encased in a snug-fitting plastic or metal canister. The number of cores in the stack is based on the amount of filtering required by each system. For example, two cores might be used for something like a Formula 1 racecar; twenty, for protecting a heavy-duty industrial process.

Modern, close tolerance equipment circulates micron-sized ferrous products against which conventional filters offer poor protection. By removing aggressive and highly damaging contaminants that conventional filters normally leave behind to circulate through systems, Magnom’s magnetic filters/separators enhance system operations.

Achieving this level of performance with a conventional barrier filter would require media so fine it would both create a massive pressure drop and fill very quickly and require costs and downtime for maintenance and replacement.

Here’s the Bottom Line

Once again, the key is simplicity.

As inline systems operate, the circulating fluids will pick up ferrous impurities. Magnom’s Magnetic Filters separates the debris and returns clean fluids to the critical components of the system.

Magnom fluid filter products are as versatile as you could hope for. They protect both high- and low-pressure systems, and perform in a wide array of temperatures, viscosities, flow rates, and dynamics. The Magnetic Filters clean a vast range of fluids — fuels, lubricants, hydraulic oils, transmission & cooling fluids, cutting oils, water, and even 95/5 hydraulic oil such as phosphate esters (e.g. Skydrol™).

Additionally, Magnom fluid filter products support all operating regimes and offer a fit-and-forget situation for many closed loop systems.

Independent testing confirms that Magnom Magnetic Filters outperform other magnetic and conventional filters, delivering up to 100% Single Pass Efficiency on sub-10 micron particles.

Now’s the time to complement or replace your customers’ and your inline fluid systems’ conventional barrier filters.

Now’s the time for Magnom™ Magnetic Filters.

Future-Proofing of Hydraulic and Lubrication Systems

Stop premature pump, motor, valve and actuator failure by implementing Magnom filters.

Learn how to improve performance, reliability and availability here.

The Ultimate Hydraulic and Lubrication System Reliability and Protection

Review independent oil analysis proving the effectiveness of Magnom’s magnetic filtration technology.

Check out the evidence here.

Starting up a hydraulic machine after an extended period of time? Check out the recap of our Hydraulic Cold Start-Up Procedures Explained for critical tips to ensure your machine starts smoothly.

In 13 quick steps, learn how to avoid machine failure by watching “Hydraulic Cold Start-up Procedures Explained” or reading the steps in our recap blog post.