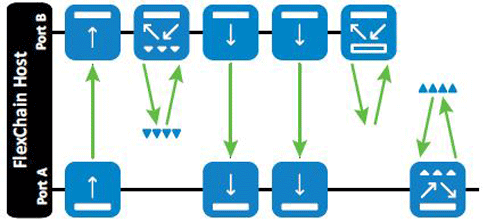

FlexChain is a unique concept in machine sensor control technology from SICK that offers any machine builder or controls designer a simplified and flexible approach to sensor connectivity. The automatic light grid technology allows any combination of up to 60 sensors to be daisy-chained together but monitored individually. This connection architecture offers many advantages, which increase machine process flexibility and significantly reduce installation costs:

- Simplified plug & play connections & cable routing to reduce wiring

- Eliminates numerous PLC Input Modules

- FlexChain “Sequential Cycling” eliminates sensor crosstalk allowing sensors to be positioned in any manner

- Industry 4.0 Ready – Sensors can be installed to allow machine flexibility to run multiple processes or products

- Provides detailed sensor diagnostic data in addition to sensor status to reduce machine downtime

- Quickly view FlexChain sensor statuses via SICK’s free SOPAS visual software tool

- FlexChain is connected via a single port on an IO-Link master module

- No network programming is required

Fields of Application

- Storage and conveyor

- Access control

- Protrusion monitoring as well as object and rough height classification

- Leading-edge detection and rough width classification

Save time and money with simple installation and implementation

The FlexChain system is easier to integrate into your existing system thanks to cascading the individual sensors. Save on cabling and easily connect to additional sensors, as they are available with different pigtails. The entire automatic light grid system works as one unit, leaving complex wiring systems behind.

More efficient integration

Save time and money during FlexChain system integration thanks to automatic sensor detection and cascaded cabling. The installation and implementation of the system is incredibly simple.

Cost-effective: Save money on cables, as sensors come with integrated pigtails

Minimal effort: Cascading individual sensors is easier than point-to-point connections

Instant-on: Data transmission starts with the simple touch of a button as the FlexChain automatically detects all sensors

Greater flexibility with measurement certainty

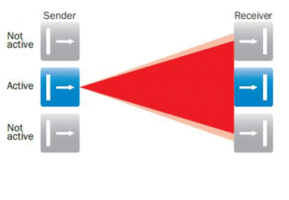

The intelligent light grid technology from SICK has sequential cycling, which prevents the signals of individual sensors from overlapping. This allows the FlexChain system to fit individual conditions and narrow arrangements. There is freedom to select various sensors, including through-beam photoelectric sensors, proximity sensors and retro-reflective sensors, providing ultimate flexibility.

More flexible positioning

FlexChain can be easily adapted to suit any application’s needs. The reliable system provides results regardless of the sensor arrangement or technology used.

Optimum measurement certainty: Avoid overlapping with sequential cycling

Freely positionable: Beams can be positioned wherever they are needed thanks to individual lengths of cables

FlexChain, the individual light grid: Sensor technology can be freely selected and combined

Complete transparency for system and sensor data

FlexChain offers flexibility for sensor data, which is either forwarded directly to the controller or evaluated in the system. FlexChain also offers extensive diagnostic options. Information such as sensor information, contamination level and communication status can be viewed anytime, allowing errors to be quickly detected and corrected.

Intelligent functionality

FlexChain can be easily and reliably integrated into virtual any environment with its numerous interfaces. Its real-time diagnostics and flexible data transmissions contribute to the ease of integration and operation.

Intuitive operation: Use free SOPAS software to define zones, configure logic and monitor the sensors with a convenient connection via USB

Numerous interfaces: Integration into nearly every system is possible

High process reliability: Prevent downtime or measurement errors with diagnostic parameters that are readily available

To learn more about SICK’s FlexChain solution, visit here.