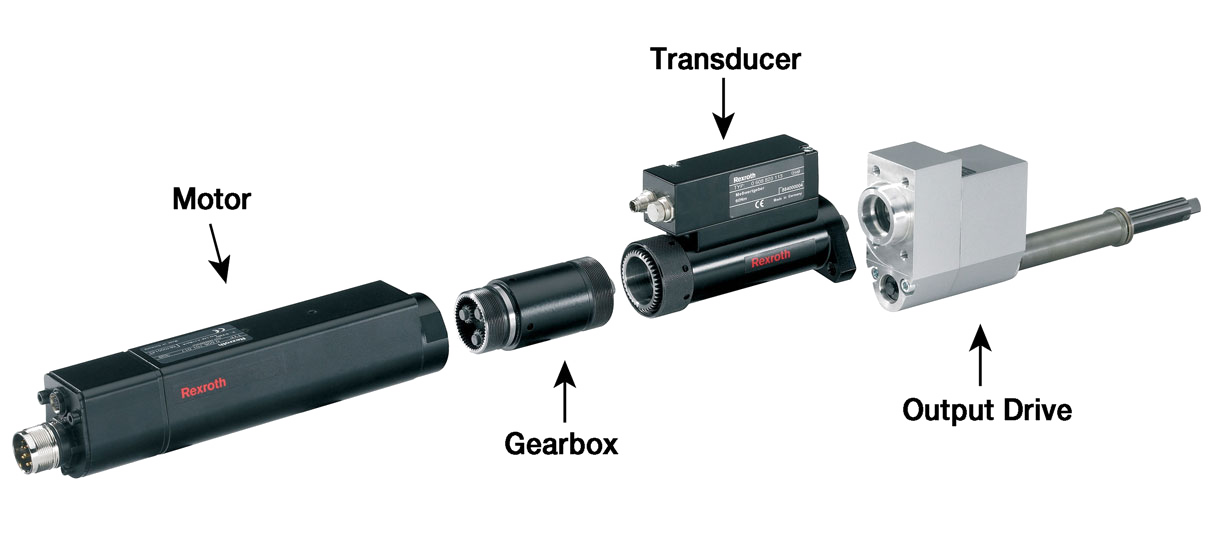

The Bosch Rexroth Tightening DC electric spindles are ideal for critical fastening applications that require data collection of assembly operations, such as torque, angle, and time. The standard offering of these intelligent fastening spindles operate between 0.6 and 1000 Nm. Options for output drives include straight drives, offset drives, feed drives, angle heads, and custom outputs. There are multiple options for gearboxes on the spindle for each size of fixture tool. In addition, there are multiple transducer options for optimal range and accuracy of the tool that requires no tuning. Furthermore, the motors in the tool do not require tuning.

Modularity of the Tightening Spindle

Bosch Rexroth tightening spindles are modular, are maintenance-free for 1 million full-load cycles, and are designed for safety critical fastening and assembly applications.

- Modular design to reduce inventory, allow custom tool design, and minimize factory downtime

- Sturdy tools designed to achieve 1 million full-load cycles before sending to customers

- Robust tools developed for safety and function critical operations to meet 21st century industry requirements

Output Spindle Options

Inline

0.6 – 500 NM

Angle Head

2.2 – 220 Nm

Feed Output

0.6 – 138 Nm

Offset Output

0.6 – 1000 Nm

Integrated Offset Output

3.2 – 342 Nm

Custom Design

Nm As Requested

There are software packages available for data collection and statistical process control for live monitoring of bolt torqueing to monitor tightening operations. Bosch Rexroth offers multi-tool controllers for operating both hand tools and fixture tools with one control box. These controllers have the capability to synchronize up to 40 tools with only 7 controllers resulting in significant space and cost savings.

Controls System

The modular control system from Bosch Rexroth can be upgraded up to 40 tightening channels. The flexible programmable logic integrated in the system is in compliance with IEC 61131-3 and allows countless automation options for the entire tightening process.

- Safe and fast commissioning

- Combination of tightening spindles and ErgoSpin

- Multi-channel tightening system

- Unused slots must be closed off with dummy panels

Software

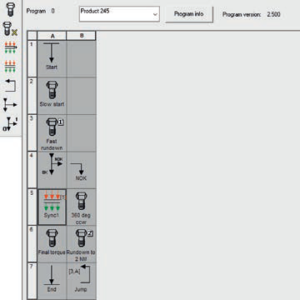

Bosch Rexroth offers Windows Based BS350 software for the Spindle tools. The BS350 software is icon-based and has a maximum of 99 programs with 40 steps per program. Each step in the program can be monitored to ensure the joint is tightened to the required specification. The BS350 software package provides the ability to analyze torque graphs, view tightened results, and observe histograms as well as see the good range window on the final step in the rundown process.

Intuitive, Reliable Tightening Processes

System installation and programming of individual tightening tasks is done via convenient, icon-supported tools. Tightening processes are configures on the graph interface.

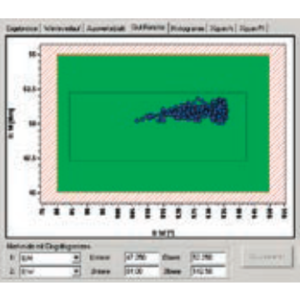

Graph

The tightening graph helps you quickly analyze tightening cases.

Good Range Window

The good range window clearly shows you the location of the tightening results in the target window.

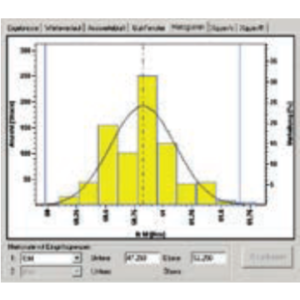

Histogram

The histogram gives you a quick overview of the statistical distribution of the tightening results.

Results Window

Internal results memory of up to 40,000 tightening results and filter search functionallty.

For more technical information on Rexroth’s Spindle Tools, visit Rexroth’s online resources here.