Achieve infinite position control with AVENTICS’ Electro-Pneumatic Positioning System (EPPS). Pneumatic-positioning systems are an efficient and cost-effective solution for precise position control. They have minimal moving parts and do not require significant energy to move or position a load. The AVENTICS EPPS utilizes direct-acting proportional regulation instead of directional flow, which eliminates dithering. This also allows the electro-pneumatic positioning system to achieve dynamic response and repeatability, resulting in a higher-performing, more efficient automated system.

Electro-Pneumatic Position System Features

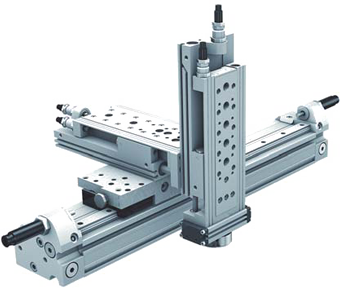

The electro-pneumatic positioning system from AVENTICS can be adapted to various actuator sizes along with pistons and rodless cylinders. The EPPS uses an externally mounted sensor, which eliminates the need for gun drilling. The efficiently designed system has fewer moving components, which reduces installation time and future repair costs.

The electro-pneumatic positioning system allows users to achieve accuracy within 1% of a stroke. The system uses a custom closed-loop position controller with a 12-bit resolution that does not require any programming. The controller has analog command, and feedback is 0-10Vdc or 4-20mA. The controller is easy to install and adjustable in the field. To further simplify the system, a single part number for the controller covers all configurations.

The electro-pneumatic positioning system utilizes series ED02 E/P valves for true closed-loop feedback control and consistent pressure regulation. The ED02 is flexible and can be mounted on a panel. SM6 series distance measurement sensors are also used in the EPPS. The sensors are IP65 and IP67 protection class with two LED displays. They have a 3 m/sec sampling speed with full stroke and a teachable measurement range.

The small footprint of the electro-pneumatic positioning system saves critical factory floor space without compromising performance. The single-part number kits for EPPS eliminate order complications. AVENTICS uses “off the shelf” components for EPPS, so you do not have to worry about long lead times and slow production.