Sun Hydraulics offers many small solenoid and non-solenoid pilot valves that can be used to provide directional pilot control. Pilot controls that feature a T-8A cavity can also be directly installed into the hex end of many of Sun’s pilot operated and ventable cartridges to provide integrated pilot control. Pilot offerings include:

- 2-way and 3-way 5000 psi (350 bar) solenoid cartridges

- Hydraulically operated 2-positon, 2-way and 2-position, 3-way pilot cartridges

- Air piloted 2-position, 2-way and 2-position, 3-way pilot controls

- Manually operated, 2-position, 2-way, intermittent pilot control

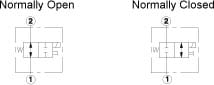

2-position 2-way, Spool Directional Valve – Pilot Capacity

- Maximum operating pressure = 5000 psi

- Maximum leakage at 150 SUS = 10 drops/min. at 5000 psi

- Switching frequency = 15000 cycles/hour

- Cartridge can be installed directly into a cavity in some Sun pilot operated and ventable cartridges to provide electrically operated pilot control functions.

- Proper installation of solenoid valves requires an extra deep socket to clear the solenoid tube.

- Sockets are available from Snap On tools (P/N SIML280) or Sun Hydraulics (P/N 998-100-006).

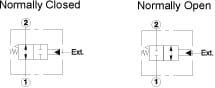

Hydraulically Operated, 2-position 2-way, Spool Directional Valve – Pilot Capacity

- Maximum operating pressure = 5000 psi

- Maximum leakage at 150 SUS = 10 drops/min. at 5000 psi

- Minimum pilot pressure to operate = 200 psi

- All ports will accept 5000 psi including the pilot control port.

- The preferred flow path through the valve is port 2 to port 1.

- The main stage valve should first be installed to the correct torque value followed by the T-8A pilot control section into the main stage valve to its required torque value.

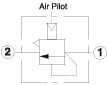

Air-operated, 2-position 2-way, Spool Directional Valve – Pilot Capacity

- Maximum operating pressure = 5000 psi

- Maximum leakage at 150 SUS = 10 drops/min. at 5000 psi

- Maximum pilot pressure = 70 psi

- Minimum pilot pressure to operate = 20 psi + port 1 pressure/100 psi

- All ports will accept 5000 psi with the exception of the pilot port which accepts 500 psi maximum.

- The preferred flow path through the valve is port 2 to port 1.

- The main stage valve should first be installed to the correct torque value followed by the T-8A pilot control section into the main stage valve to its required torque value.

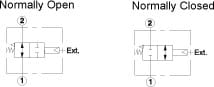

Manually Operated, 2-position 2-way, Spool Directional Valve – Pilot Capacity

- Maximum operating pressure = 5000 psi

- Maximum leakage at 150 SUS = 10 drops/min. at 5000 psi

- The preferred flow path through the valve is port 2 to port 1.

- The main stage valve should first be installed to the correct torque value followed by the T-8A pilot control section into the main stage valve to its required torque value.

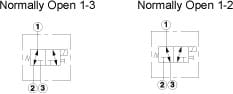

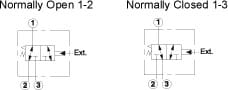

2-position 3-way, Spool Directional Valve – Pilot Capacity

- Maximum operating pressure = 5000 psi

- Maximum leakage at 150 SUS = 10 drops/min. at 5000 psi

- Switching frequency = 15000 cycles/hour

- Proper installation of solenoid valves requires an extra deep socket to clear the solenoid tube.

- Sockets are available from Snap On tools (P/N SIML280) or Sun Hydraulics (P/N 998-100-006).

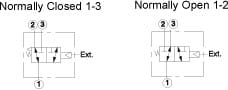

Hydraulically Operated, 2-position 3-way, Spool Directional Valve – Pilot Capacity

- Maximum operating pressure = 5000 psi

- Maximum leakage at 150 SUS = 10 drops/min. at 5000 psi

- Minimum pilot pressure to operate = 200 psi

- All ports will accept 5000 psi including the pilot control port.

Air-operated, 2-position 3-way, Spool Directional Valve – Pilot Capacity

- Maximum operating pressure = 5000 psi

- Maximum leakage at 150 SUS = 10 drops/min. at 5000 psi.

- Maximum pilot pressure = 70 psi

- Minimum pilot pressure to operate = 20 psi + port 1 pressure/100 psi

- All ports will accept 5000 psi with the exception of the pilot port which accepts 500 psi maximum.

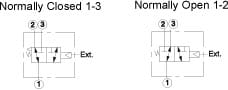

- Maximum operating pressure = 5000 psi

- Maximum leakage at 150 SUS = 10 drops/min. at 5000 psi

- All ports will accept 5000 psi.

Direct Acting, Adjustable Pilot Relief

- Maximum operating pressure = 5000 psi

- Maximum leakage = 5 drops/min. at reseat (reseat = 85% of cracking pressure).

- Ports 1 and 2 may be pressured to 5000 psi.

- Back pressure at port 2 (outlet) is directly additive to the pressure setting at port 1 (inlet).

- The main stage valve should first be installed to the correct torque value followed by the T-8A pilot control section into the main stage valve to its required torque value.

Air-controlled, Directing Acting Pilot Relief

- Maximum operating pressure = 5000 psi

- Maximum leakage = 5 drops/min. at 5000 psi

- Maximum pilot pressure = 150 psi

- Ports 1 and 2 may be pressured to 5000 psi.

- Back pressure at port 2 has no effect on the valve setting.

- The main stage valve should first be installed to the correct torque value followed by the T-8A pilot control section into the main stage valve to its required torque value.

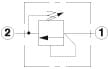

Fully Adjustable Needle Valve – Pilot Capacity

- Maximum operating pressure = 5000 psi

- Maximum leakage at shutoff = less than 5 drops/min. at 5000 psi

- Effective orifice size = 0.035 in.

- Number of counterclockwise turns fully closed to fully open = 3

- Ports 1 and 2 may be pressured to 5000 psi.

Electro-proportional Pilot Relief

- Maximum operating pressure = 5000 psi

- Maximum leakage = 1.5 in³/min at reseat

- Back pressure on the tank port (port 2) is directly additive at a 1:1 ratio to valve setting

- Reseat exceeds 85% of cracking pressure.

- Hysteresis with dither <4%

- Hysteresis with DC input <8%

- Linearity with dither <2%

- For optimum performance, an amplifier with current sensing and adjustable dither should be used.

- Dither should be adjustable between 100 – 250 Hz.