Sun Hydraulics counterbalance cartridges, modulating devices for load holding and motion control, can be directly integrated into your actuator or applied using manifolds with many mounting options.

- Offer hose break protection

- Prevent loads from drifting

- Control overrunning loads

- Provide overcenter load control

- Protect against pressure due to thermal expansion

- Are physically interchangeable with pilot-to-open check cartridges (same number of ports, same cavities, same flow path for a given frame size)

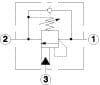

Standard, 4000 psi Maximum Setting

- Load holding to 3000 psi with 4000 psi valve setting

- Maximum valve leakage at reseat = 5 drops/min.

- Reseat exceeds 85% of set pressure

- Factory pressure setting established at 2 in³/min.

- Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

- Back pressure at port 2 adds to the effective relief setting at a ratio of 1 plus the pilot ratio times the back pressure.

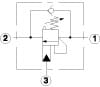

Standard, 5000 psi Maximum Setting

- Load holding to 3850 psi with 5000 psi valve setting

- Maximum valve leakage at reseat = 5 drops/min.

- Reseat exceeds 85% of set pressure

- Factory pressure setting established at 2 in³/min.

- Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

- Back pressure at port 2 adds to the effective relief setting at a ratio of 1 plus the pilot ratio times the back pressure.

Semi-Restrictive, 4000 psi Maximum Setting

- Load holding to 3000 psi with 4000 psi valve setting

- Maximum valve leakage at reseat = 5 drops/min.

- Reseat exceeds 85% of set pressure

- Factory pressure setting established at 2 in³/min.

- Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

- Back pressure at port 2 adds to the effective relief setting at a ratio of 1 plus the pilot ratio times the back pressure.

Semi-Restrictive, 5000 psi Maximum Setting

- Load holding to 3850 psi with 5000 psi valve setting

- Maximum valve leakage at reseat = 5 drops/min.

- Reseat exceeds 85% of set pressure

- Factory pressure setting established at 2 in³/min.

- Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

- Back pressure at port 2 adds to the effective relief setting at a ratio of 1 plus the pilot ratio times the back pressure.

Restrictive, 4000 psi Maximum Setting

- Restrictive valves have no relief capacity other than as a thermal relief.

- Load holding to 3075 psi with 4000 psi valve setting

- Maximum valve leakage at reseat = 5 drops/min.

- Reseat exceeds 85% of set pressure

- Factory pressure setting established at 2 in³/min.

- Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

- Back pressure at port 2 adds to the effective relief setting at a ratio of 1 plus the pilot ratio times the back pressure.

Restrictive, 5000 psi Maximum Setting

- Restrictive valves have no relief capacity other than as a thermal relief.

- Load holding to 3850 psi with 5000 psi valve setting

- Maximum valve leakage at reseat = 5 drops/min.

- Reseat exceeds 85% of set pressure

- Factory pressure setting established at 2 in³/min.

- Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

- Back pressure at port 2 adds to the effective relief setting at a ratio of 1 plus the pilot ratio times the back pressure.

Without Pilot Assist, 3 Port Cavity

- Maximum operating pressure = 4000 psi

- Maximum valve leakage at reseat = 5 drops/min.

- Reseat exceeds 85% of set pressure

- Factory pressure setting established at 2 in³/min.

- Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

- Back pressure at port 2 is directly additive to the relief setting of the valve.

Atmospherically Referenced, 3 Port Cavity

- Load holding to 3000 psi with 4000 psi valve setting for CA*A, CA*K; 4600 psi with 6000 psi valve setting for CA*G, CA*L.

- Maximum valve leakage at reseat = 5 drops/min.

- Reseat exceeds 85% of set pressure

- Factory pressure setting established at 2 in³/min.

- Free flow check cracking pressure = 40 psi

- Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

Vented, 4000 psi Maximum Setting

- Load holding to 3000 psi with 4000 psi valve setting

- Maximum valve leakage at reseat = 5 drops/min.

- Reseat exceeds 85% of set pressure

- Factory pressure setting established at 2 in³/min.

- Free flow check cracking pressure = 40 psi

- Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

Vented, 6000 psi Maximum Setting

- Load holding to 4600 psi with 6000 psi valve setting

- Maximum valve leakage at reseat = 5 drops/min.

- Reseat exceeds 85% of set pressure

- Factory pressure setting established at 2 in³/min.

- Free flow check cracking pressure = 40 psi

- Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

Vented, 6000 psi Maximum Setting

- Load holding to 4600 psi with 6000 psi valve setting

- Maximum valve leakage at reseat = 5 drops/min.

- Reseat exceeds 85% of set pressure

- Factory pressure setting established at 2 in³/min.

- Free flow check cracking pressure = 40 psi

- Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.