Machine Risk Assessment

It is obvious that the wrong interpretation of a machines risk reduction requirements can lead to costly and perhaps, catastrophic mistakes. Couple this with a multitude of national, state, and local safety standards that may apply to a specific machine type and it is no wonder that there is so much confusion among equipment builders and end users who are tasked with making these decisions.

Broad knowledge of these standards is only one piece to this puzzle. The responsible party must not only select the correct, applicable standard for the specific machine type, but they must also then read, interpret and apply the standard with consideration to the following variables.

- Severity of Injury

- Exposure, Duration, Extent

- How many people are exposed to the hazard

- Workplace environment

- Reliability of existing safety functions

- Human interference with safety precautions

- Level of training, skill and experience

- Machine history – maintenance, reliability and age

- Possibility to defeat protective measures

- Ability to maintain protective measures

These variables must be addressed to achieve a level of safety that is consistent with the level of risk.

Documentation

CE compliance demands that risk assessment be completed and documented. Until recently, risk assessment and documentation only applied to those who wished to export products to member states in the EU. A few US corporations have voluntarily implemented their own risk analysis programs. While their decision to take this step is admirable, the reality is that their efforts are often inconsistent and misinformed.

Times have changed. Recent major re-writes to the NFPA 79 and B11.TR3 clearly require documented risk assessment on all new machines and all existing machines when upgraded/ modified. This requirement will be enforced by OSHA. See “Concepts and Techniques of Machine Safeguarding” OSHA CFR 3067.

Newly integrated module for CE compliance, ISO 13849 with all its subsets. (ISO 12100, ISO 14119, etc.)

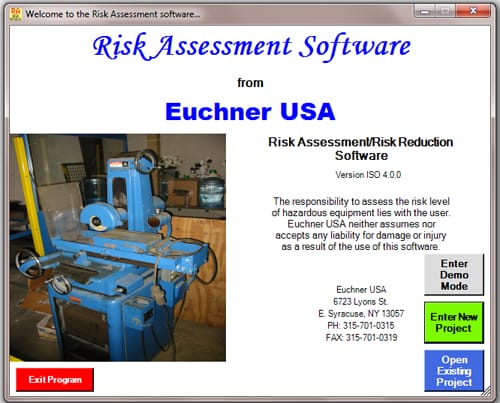

Risk Assessment Automation is Critical

- Verifies that all aspects of machine operation and maintenance are identified and addressed.

- Ensures that the correct ANSI Category and Sub-Category are applied.

- Ensures consistency within multi- plant corporations.

- Networkable risk assessment software can be shared between multi-plant corporations eliminating duplication of efforts & inconsistencies.

- Software covers control reliability of electric, electronic, pneumatic, and hydraulic functions of the machine, not just your safety switches.