Diffuse

A diffuse-mode, or energetic-diffuse, photoelectric sensor is a reflective sensor, containing a transmitter and a receiver in a single housing. The sensor emits a light beam toward a distant target that acts as a reflector, returning part of the transmitted light to the sensor. The receiver detects the amount of light reflected by the target, triggering the sensor when the light intensity reaches a threshold value.

Diffuse-mode sensors are cost-effective as they do not require separate reflectors or receivers, and detect reflective targets with ease. Sensing range depends on the target’s size, shape, color and surface finish, although sensor sensitivity is adjustable during installation to compensate for targets with poor reflective qualities.

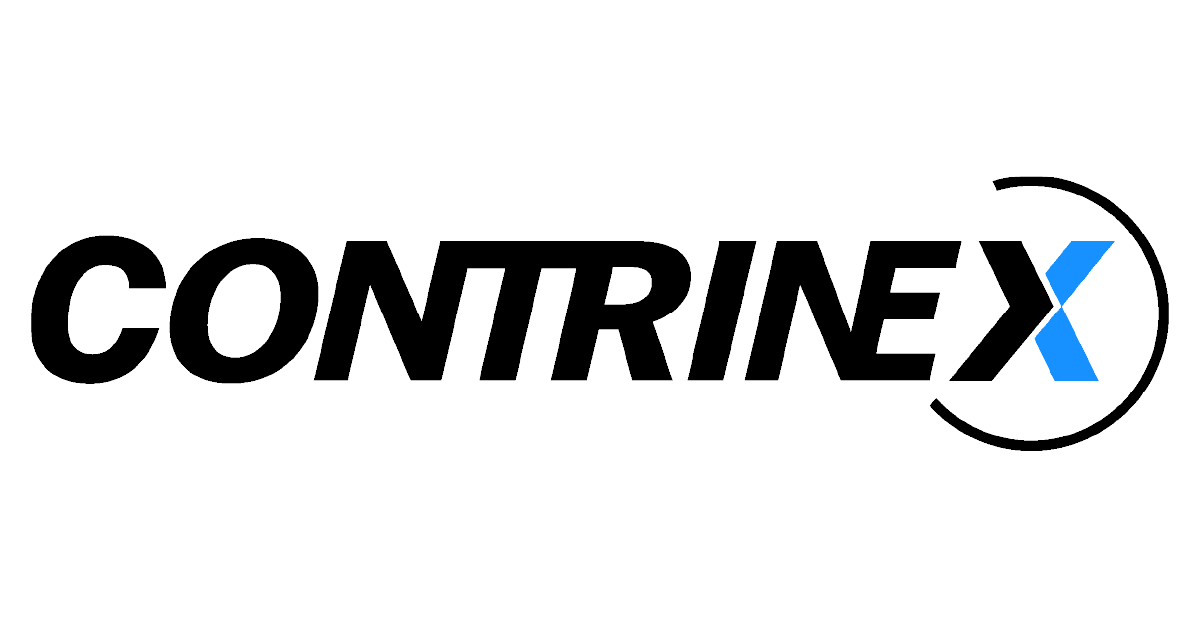

Background Suppression

Diffuse-mode photoelectric sensors with background suppression emit a focused light beam toward a distant target. Part of the beam is reflected from the target and returns to the sensor, striking a position-sensitive receiver. The receiver distinguishes between reflections from the target and reflections from background objects, only triggering the sensor when the signal reaches a value that corresponds to the preset target distance.

The sensing mode is practically insensitive to the target’s size, color, shape and surface finish, and background-suppression sensors provide highly reliable detection of “difficult” targets, even against a light background. Stable, accurate detection of small, fast-moving parts on conveyors or automated machinery is possible over the entire sensing range, eliminating false triggering by objects in the background.

Reflex

A reflex, or reflective, photoelectric sensor contains a transmitter and a receiver in a single housing, and emits a pulsed, focused light beam through a polarization filter toward a distant reflector. Reflected light returns to the sensor, passing through a second filter before arriving at the receiver. When a target object interrupts the light beam, the receiver detects the reduced light intensity and triggers the sensor. The relatively high level of reflected light allows reflex sensors to achieve sensing distances up to six meters, and the polarization filters prevent light reflected by other objects from reaching the receiver, ensuring reliable detection, even with reflective targets.

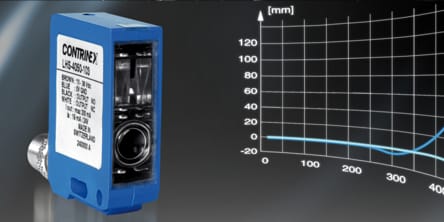

Analog Output

Photoelectric sensors with analog outputs are ideal for measuring values of distance. Using triangulation technology, analog photoelectric sensors produce an output signal that is accurately calibrated and approximately proportional to the distance of the target from the sensor. Users have a choice of current or voltage outputs that are compatible with all modern control systems. Contrinex analog photoelectric sensors provide all the advantages of standard diffuse-mode sensors, and measure target distances up to 100mm.High-precision laser analog sensors offer minimum resolution of 40 micrometers at 60mm range, while visible red-light sensors are accurate to 3mm at 100mm range.

Thru Beam

A through-beam photoelectric sensor comprises a transmitter and receiver, each mounted in a separate housing. The transmitter emits an aligned, pulsed beam of light toward the receiver, which is mounted beyond the target area. The target interrupts the light beam and triggers the sensor, causing the output signal to switch. Contrinex through-beam photoelectric sensors are ideal for industrial applications where sensing components must be mounted some distance from the target area. Through-beam sensors utilize infrared, visible and laser light sources to detect opaque and semi-transparent targets, reliably and repeatably, at extended distances.

Color

Color photoelectric sensors utilize energetic-diffuse sensing technology to detect variations in target color, allowing color sorting or color control that is independent of target speed or distance. Using a “teach-in” function to program up to three separate outputs, the sensor recognizes or ignores even the smallest variations of shade. Ideal for automated production processes that need reliable, repeatable color detection for accurate quality control, Contrinex color photoelectric sensors feature five selectable tolerance levels for each shade of color. Robust design ensures that sensor performance is unaffected by varying ambient light levels.

Optical Amplifier

Fiber-optic sensors are common in explosive environments or in the presence of strong electromagnetic fields – in these areas, sensors that rely on electrical signals may present a risk of explosion or fail to operate correctly. Contrinex manufactures world-class fiber-optic sensors and amplifiers that not only meet these needs, but also present a highly practical means of sensing in confined spaces. With bend-radii as small as 2mm, reliable, accurate sensing is possible even in the most inaccessible areas. With self-contained fiber-optic sensors available in housings as small as 30mm x 30mm x 15mm, and several models of small DIN-rail mounted amplifiers that accommodate multiple-sensor applications, the Contrinex range is highly versatile. A choice of synthetic optical fibers with impressively low attenuation rates for general use or glass optical fibers for high ambient temperatures and aggressive environments provides options for even the most demanding applications.