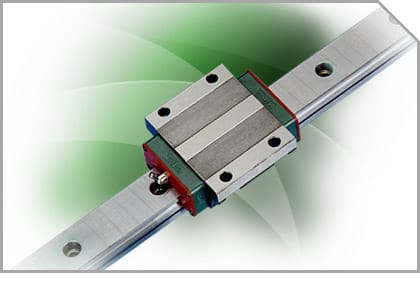

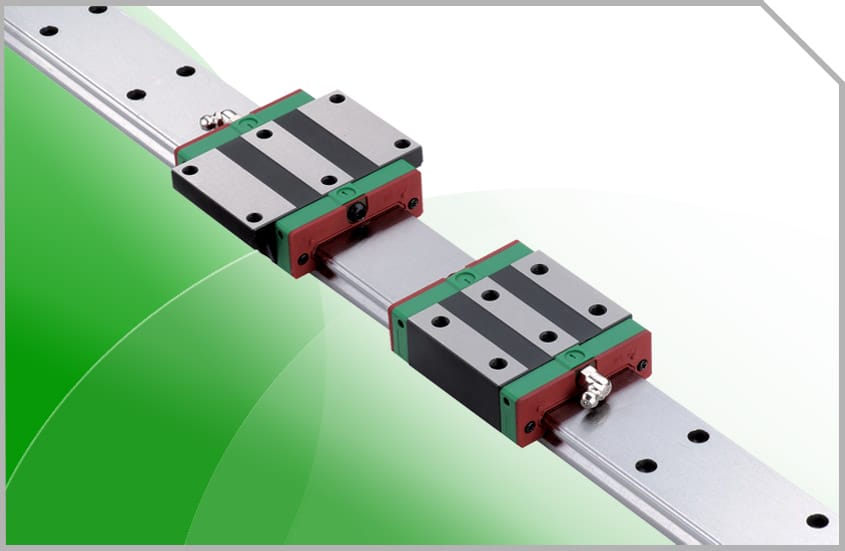

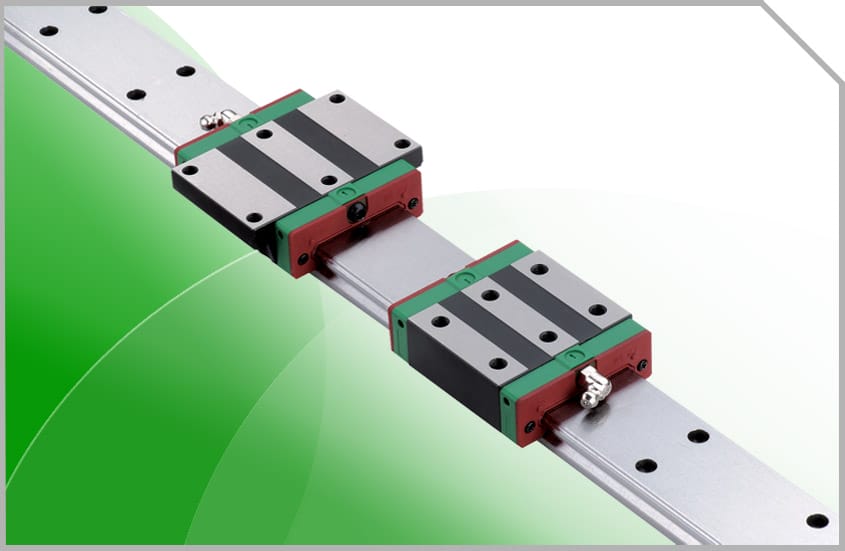

HG Series

Applications:

- Machining centers

- Machine tools

- Heavy cutting machines

- Grinding machines

- Injection molding machine

- Automatic equipment

- High speed transfer device

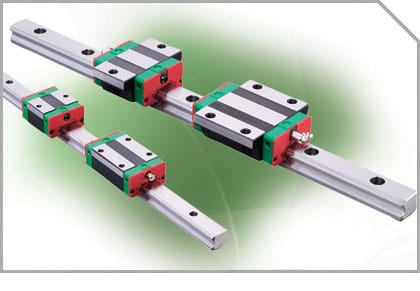

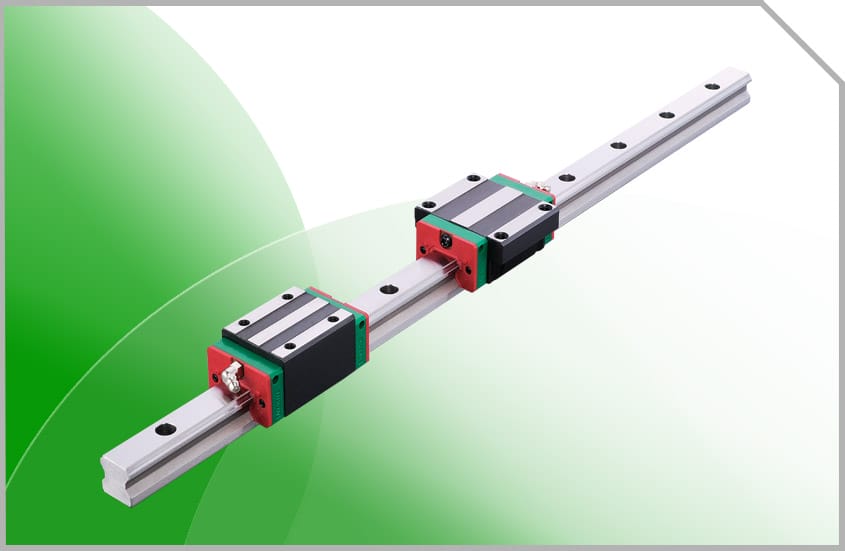

EG Series

Applications

- Automation devices

- High-speed transportation equipment

- Precision measuring equipment

- Semiconductor manufacturing equipment

- Woodworking machinery

Model EGW15CCZ0C – STOCKED ITEM

Flange Style, Size 15, Short Block, Mounting From Top or Bottom, Z0 Preload, C Precision

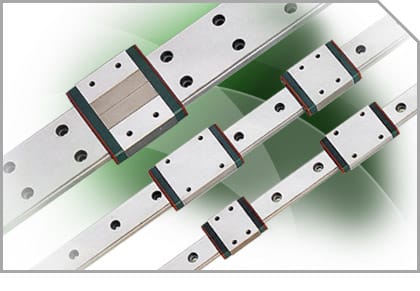

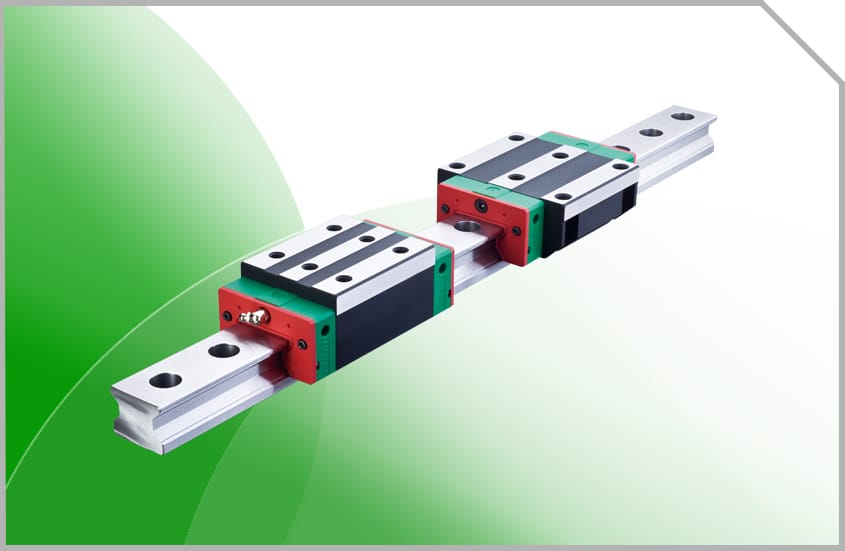

MG Series

Applications:

- Miniature Device

- Medical Equipment

- IC Manufacturing

- Wood Cutting

- X-Y Table

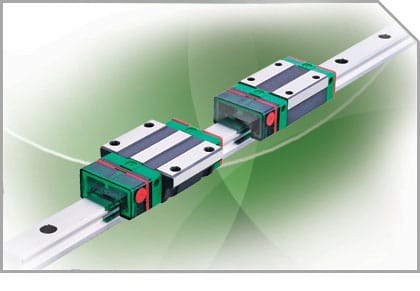

E2 Series

Applications:

- Machine Tools

- Manufacturing Machines:

Plastic injection, printing, paper making, textiles, food processing, wood working, etc. - Electronic Machines:

Semiconductor equipment, robots, X-Y table, measuring and inspecting equipment. - Others:

Medical equipment, transporting device, housing equipment.

QW Series

The QW Linear Guideway series with SyncMotion Technology possesses all the advantages of the WE series, which features high moment rigidity and is suitable for single rail or space saving applications. With the SyncMotion technology it also provides quieter and smother movment, superior lubrication, and longer service life.

Features:

– Smooth Movement In standard linear guideways, rolling elements on the load side of the guide block begin rolling and push their way through the raceway. When they contact other rolling elements they create counter-rotational friction. This results in a great variation of rolling resistance. The QW linear guideway, with SynchMotionTM technology prevents this condition. As the block starts to move, the rolling elements begin rolling consecutively and remain separated to prevent contact with one another thus keeping the element’s kinetic energy extremely stable in order to effectively reduce fluctuations in rolling resistance.

– Low Noise Design With SynchMotionTM technology, rolling elements are interposed between the partitions of SynchMotionTM to provide improved circulation. Due to the elimination of contact between the rolling elements, collision noise and sound levels are drastically reduced.

QE Series

HIWIN-QE series guideway can be classified into non-interchangeable and interchangeable types. The sizes are

identical. The main difference is that the interchangeable blocks and rails can be freely exchanged. Because of

dimensional control, the interchangeable type linear guideway is a perfect choice for the client when rails do not need

to be paired for an axis. And since the QE and EG share the identical rails, the customer does not need to redesign

when choosing the QE series. Therefore the HIWIN-QE linear guideway has increased applicability.

QH Series

The QR Linear Guideway series offers super high rigidity and very high load capacities. Combined with SyncMotion Technology the QR series offers low friction, smoth movment, quieter operation and longer running life. In the industry where high accuracy, low noise and high rigidity, the QR series is interchangeable with the RG series. Features: – Low Noise Design With SynchMotion TM technology, rolling elements are interposed between the partitions of SynchMotion TM to provide impoved circulation.

Due to the elimination of contact between the rolling elements, collision noise and sound levels are drastically reduced.

– Self-Lubricant Design The partition is a grouping of hollow ring-like structures formed with a through hole to facilitate circulation of the lubricant. Because of the special lubrication path design, the lubricant of the partition storage space can be refilled. Therefore, the frequency of lubricant refilling can be decreased.

The QH-series linear guideway is pre-lubricated. Performance testing at a 0.2C (basic dynamic load) shows that after running 2,500km no damage was apparent to either the rolling elements or the raceway.

– Smooth Movement In standard linear guideways, rolling elements on the load side of the guide block begin rolling and push their way through the raceway.

When they contact other rolling elements they create counter-rotational friction. This results in a great variation of rolling resistance.

The QH linear guideway, with SynchMotion TM technology prevents this condition. As the block starts to move, the rolling elements begin rolling consecutively and remain separated to prevent contact with one another thus keeping the element’s kinetic energy extremely stable in order to effectively reduce fluctuations in rolling resistance.

– High Speed Performance The Hiwin-QH series offers excellent high-speed performance due to the partitions of the SynchMotion TM structure.

They are employed to separate the adjacent balls thereby resulting in low rolling traction and the metallic friction between adjacent balls is eliminated.

QR Series

The QR Linear Guideway series offers super high rigidity and very high load capacities. Combined with SyncMotion Technology the QR series offers low friction, smoth movment, quieter operation and longer running life. In the industry where high accuracy, low noise and high rigidity, the QR series is interchangeable with the RG series.

Features:

– Smooth Movement: In standard linear guideways, rolling elements on the load side of the guide block begin rolling and push their way through the raceway. When they contact other rolling elements they create counter-rotational friction. This results in a great variation of rolling resistance. The QR linear guideway, with SynchMotionTM technology prevents this condition. As the block starts to move, the rolling elements begin rolling consecutively and remain separated to prevent contact with one another thus keeping the element’s kinetic energy extremely stable in order to effectively reduce fluctuations in rolling resistance.

– Low Noise Design With SynchMotionTM technology: Rolling elements are interposed between the partitions of SynchMotionTM to provide improved circulation. Due to the elimination of contact between the rolling elements, collision noise and sound levels are drastically reduced.

– Super High Load Capacity: With the four rows of rollers arranged at a contact angle of 45-degrees, the QR series linear guideway has equal load ratings in the radial, reverse radial and lateral directions. The QR series has a higher load capacity in a smaller size than conventional, ball-type linear guideways.

– The QR series is a type of linear guideway that uses rollers as the rolling elements.

Elastic deformation of the linear contact surface, during load, is greatly reduced thereby offering greater rigidity and higher load capacities in all 4 load directions.

RG Series

Applications:

- CNC Machining Centers

- Heavy Duty Cutting Machines

- CNC Grinding Machines

- Injection Molding Machines

- Plano Millers

- Electric Discharge Machines

SE Series

This option increases temperature resistance.

Service temperatures from under 150°C and instance temperatures up to 200°C.

Applications:

- Heat treatment equipment, welding machines, glass manufacturing, vacuum (without vapor dispersion from plastic or rubber at high temperatures).

WE Series

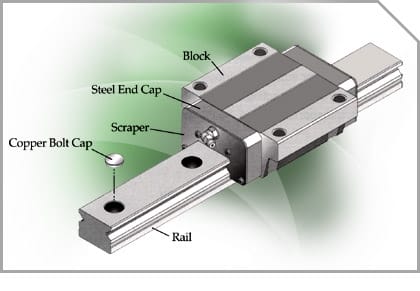

The WE series features equal load ratings in the radial, reverse radial and the lateral direction with contact points at 45 degrees. This along with the wide rail, allows the guideway to be rated for high loads, moments and rigidity. By design, it has a self-aligning capability that can absorb most installation errors and can meet high accuracy standards. The ability to use a single rail and to have the low profile with a low center of gravity is ideal where space is limited and/or high moments are required. Features: – Rolling circulation system: Block, rail, end cap and retainer.

– Lubrication system: Grease nipple and piping joint.

– Dust protection system: End seal, bottom seal, scraper and rail cap.