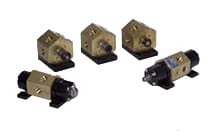

Hi-Cyclic® Mechanically Operated Directional Control Valves

2,000 PSI for 1/8″, 1/4″, 3/8″ and 1/2″ models (1/4″ B, BSL and BB models are rated at 1,000 PSI)

3,000 PSI for 7/16-20 or 9/16-18 SAE models

Hi-Cyclic® is a directional control valve line that has become synonymous with operating dependability over many years of service. One reason for such an association to quality is our solid brass body that serves as a strong foundation for durability, allowing our valves to stand up to even the most severe applications. A second reason for them being so rugged is our sleeveless spool-to-body design. Internal restrictions are kept to a minimum, resulting in a very efficient high flow valve. Each spool is individually matched to a body, so Hi-Cyclic® valves function with a precision fit that reduces internal leakage to a minimum. We also use a simple, basic design principle — we keep moving parts and wear points to a minimum.

The key to the product’s versatility is in its modular component design. We use a few basic body styles that can be joined with a number of spool, operator and mounting options to create a magnitude of combinations. Because of our non-ferrous construction, we can handle air or hydraulic oils with pressures from 30″ Hg vacuum to 250 PSI in air service, and up to 3,000 PSI when used in hydraulic service. Models are available in 1/8″ NPT to 1/2″ NPT as well as 7/16-20 and 9/16-18 SAE straight thread port sizes with foot or subplate mounts (Magna-Cycle® only). Hi-Cyclic® valves may be specified with almost any type of direct solenoid, direct pilot (air or hydraulic), manual or mechanical operators to meet your specific application requirements.

Hi-Cyclic® valve response characteristics are exceptional, making them ideal where rapid cycling is required. This fast action is due in part to its extremely short spool travel – only 0.217″ maximum. Rapid response is also aided by its precision honed body that is individually matched to custom lapped, pressure balanced spools, giving each valve almost frictionless operation and effortless shifting.

The valve line features a compact, space saving design. With a maximum body length of only 2-1/4″ and a maximum height of only 2-5/8″ for foot mounted models, the product line yields an extremely compact envelope size and a low silhouette for installations with limited space.

Mechanically actuated valves are ideal for integration into machine tools, production machines, or any type of machine or equipment requiring a compact, high flow valve. Operators include the basic valve with a threaded spool for custom applications in spring return and non-spring versions, a unique “ball point” operator for actuation via a sliding or rolling cam in almost any plane, a cam roller and a clevis for actuation via mechanical linkage.

| Applications include:

|

| Body | Brass Alloy 360 |

| Seals | Buna-N (See options page on Lexair web site for other seal options.) |

| Spool | 303 Stainless Steel (See options page on Lexair web site for spool functions.) |

| Port Size | See options page on Lexair web site for available port sizes.

Pilot ports are 1/4″ NPT for all air pilot versions and 7/16-20 for all hydraulic pilot versions. |

| Temperature Range | -20°F to +160°F (With Buna-N seals) |

| Pressure Rating | Pneumatic service – vacuum through 250 PSI

Hydraulic service – 2,000 PSI for 1/8″, 1/4″, 3/8″ and 1/2″ models (1/4″ B, BSL and BB models are rated at 1,000 PSI); 3,000 PSI for 7/16-20 or 9/16-18 SAE models NOTE: A minimum filtration rating of 10 microns is recommended for pneumatic or hydraulic service |

| Flow | Pneumatic 1/8″ and 1/4″ up to 1.00 Cv, 3/8″ and 1/2″ up to 1.13 Cv

Hydraulic up to 16 GPM |