HYDAC offers various options of Differential Pressure Sensing Valves for applications up to 5000 psi (350 bar) and up to 80 gpm (300 l/min).

Differential pressure sensing valves can be used for controlling pressure, flow, direction or compensation. They are functional building elements which respond to pressure inputs, providing for switching or modulation of the flow. The choice of circuit arrangements related to the Pressure Sensing valves can simplify the circuit design and minimize the size of the manifold, thus reducing manifold cost.

Features

- Operating pressure up to 5000 psi (350 bar)

- Various spring ranges

- Quiet, modulated response

- All external surfaces zinc-plated

- Hardened spool and sleeve to ensure minimal wear and extend service life

- Industry common cavity

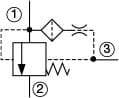

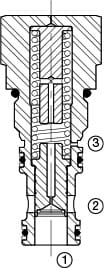

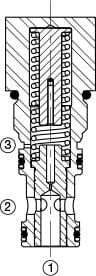

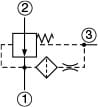

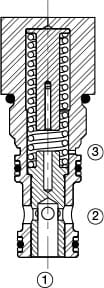

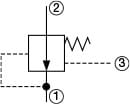

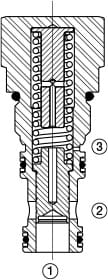

DW10SA-01

Normally Closed, Vent to Open, Spool Type

Up to 40 gpm (151 lpm) • 5000 psi (350 bar)

Description

A screw-in cartridge, pressure sensing valve with multifunction potential when used with flow, pressure and directional control devices. It can be used as high flow switching or metering element, main stage for pilot operated relief or sequence valve.

Operation

Pilot flow through the spool orifice, from port 1 to port 3 creates a pressure drop and allows flow from port 1 to port 2 when the pressure drop exceeds the spring bias pressure. The valve can be remotely controlled at port 3 such as relief or solenoid valve.

Features

- Operating pressure up to 5000 psi (350 bar)

- Various bias spring settings up to 300 psi (20.7 bar)

- Quiet, modulated response

- All external surfaces zinc-plated

- Hardened spool and sleeve to ensure minimal wear and extend service life

- Industry common cavity

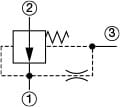

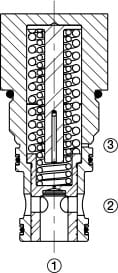

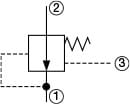

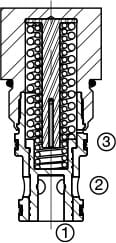

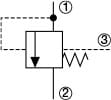

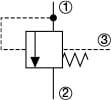

DW10SC-01

Normally Open, Vented, Spool Type

Up to 15 gpm (57 lpm) • 5000 psi (350 bar)

Description

A screw-in cartridge, spring biased, pressure sensing valve.

Operation

Pilot flow through the spool orifice, from port 1 to port 3, creates a pressure drop and tends to close the spool from port 2 to port 1 when the pressure drop exceeds the spring bias pressure. The valve can be remotely controlled at port 3 such as a relief or solenoid valve.

Features

- Operating pressure up to 5000 psi (350 bar)

- Various bias spring settings up to 300 psi (20.7 bar)

- Quiet, modulated response

- All external surfaces zinc-plated

- Hardened spool and sleeve to ensure minimal wear and extend service life

- Industry common cavity

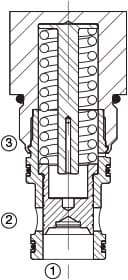

DW16SC-01

Normally Open, Vented, Spool Type

Up to 30 gpm (114 lpm) • 5000 psi (350 bar)

Description

A screw-in cartridge, spring biased, pressure sensing valve.

Operation

Pilot flow through the spool orifice, from port 1 to port 3, creates a pressure drop and tends to close the spool from port 2 to port 1 when the pressure drop exceeds the spring bias pressure. The valve can be remotely controlled at port 3 such as a relief or solenoid valve.

Features

- Operating pressure up to 5000 psi (350 bar)

- Various bias spring settings up to 300 psi (20.7 bar)

- Quiet, modulated response

- All external surfaces zinc-plated

- Hardened spool and sleeve to ensure minimal wear and extend service life

- Industry common cavity

DW10V-01

Normally Open, Spool Type

Up to 15 gpm (57 lpm) • 5000 psi (350 bar)

Description

A screw-in cartridge, pressure sensing valve intended for use upstream of a fixed or variable orifice to provide a constant flow rate regardless of load pressure changes.

Operation

The spool begins to shift when the pressure at port 1 exceeds the combined pressure at port 3 plus the bias spring pressure. It is possible to create a pressure compensated flow control package by connecting port 1 upstream and port 3 downstream of a control orifice.

Features

- Operating pressure up to 5000 psi (350 bar)

- Various bias spring settings up to 300 psi (20.7 bar)

- Quiet, modulated response

- All external surfaces zinc-plated

- Hardened spool and sleeve to ensure minimal wear and extend service life

- Industry common cavity

DW16V-01

Normally Open, Spool Type

Up to 30 gpm (114 lpm) • 5000 psi (350 bar)

Description

A screw-in cartridge, pressure sensing valve intended for use upstream of a fixed or variable orifice to provide a constant flow rate regardless of load pressure changes.

Operation

The spool begins to shift when the pressure at port 1 exceeds the combined pressure at port 3 plus the bias spring pressure. It is possible to create a pressure compensated flow control package by connecting port 1 upstream and port 3 downstream of a control orifice.

Features

- Operating pressure up to 5000 psi (350 bar)

- Various bias spring settings up to 300 psi (20.7 bar)

- Quiet, modulated response

- All external surfaces zinc-plated

- Hardened spool and sleeve to ensure minimal wear and extend service life

- Industry common cavity

DW10Z-01

Normally Closed, Spool Type

Up to 40 gpm (151 lpm) • 5000 psi (350 bar)

Description

A screw-in cartridge, pressure sensing valve with multifunction potential when used with flow, pressure and directional control devices.

Operation

The spool begins to shift allowing flow from port 1 to port 2 only when pressure at port 1 exceeds the combined pressure at port 3 plus the bias spring pressure setting. With no pressure at port 3, flow will be allowed from port 1 to port 2 once the bias spring force is overcome with pressure at port 1.

It is also possible to create pressure compensation by connecting port 1 upstream and port 3 downstream of a control orifice.

Features

- Operating pressure up to 5000 psi (350 bar)

- Various bias spring settings up to 300 psi (20.7 bar)

- Quiet, modulated response

- All external surfaces zinc-plated

- Hardened spool and sleeve to ensure minimal wear and extend service life

- Industry common cavity

DW16Z-01

Normally Closed, Spool Type

Up to 75 gpm (284 lpm) • 5000 psi (350 bar)

Description

A screw-in cartridge, pressure sensing valve with multifunction potential when used with flow, pressure and directional control devices.

Operation

The spool begins to shift allowing flow from port 1 to port 2 only when pressure at port 1 exceeds the combined pressure at port 3 plus the bias spring pressure setting. With no pressure at port 3, flow will be allowed from port 1 to port 2 once the bias spring force is overcome with pressure at port 1.

It is also possible to create pressure compensation by connecting port 1 upstream and port 3 downstream of a control orifice.

Features

- Operating pressure up to 5000 psi (350 bar)

- Various bias spring settings up to 300 psi (20.7 bar)

- Quiet, modulated response

- All external surfaces zinc-plated

- Hardened spool and sleeve to ensure minimal wear and extend service life

- Industry common cavity