HYDAC offers a wide range of direct acting and pilot operated Relief and Reducing Valves. In general, the direct acting valves are faster in response while pilot operated valves have flatter pressure/flow characteristics.

HYDAC Relief Valves are available in direct acting poppet and pilot operated spool types with optional pressure adjustment ranges up to 6000 psi (420 bar). Models are available for flow rates up to 80 gpm (300 l/min).

HYDAC Pressure Reducing Valves are direct acting and pilot operated spool types with optional pressure adjustment ranges up to 5000 psi (350 bar). They have been designed to maintain a constant secondary regulated pressure regardless of pressure variation in the primary system and have an additional relieving feature for the secondary circuit protection. Models are available for flow rates up to 26 gpm (100 l/min).

Features

- Adjustable under full pressure

- Stroke limiting device for enhanced safety

- Positive stop to prevent spring from over adjustment

- Screens to protect pilot orifice from contamination and ensure reliable operation

- Variety of adjustment mechanism options

- Fast response with excellent stability

- All external surfaces zinc-plated

- Hardened poppets or spools ensure minimal wear and extend service life

- One piece body maximizes reliability and minimizes the effects of eccentricity

- Industry common cavity-compact size

DB06A-01

Pressure Relief, Direct Acting, Ball Type

Up to 4 gpm (15 l/min) • 5000 psi (350 bar)

Description

A screw-in cartridge, direct acting, ball type relief valve intended for use as pressure limiting device in hydraulic circuits requiring low internal leakage and fast response.

Operation

The DB06A blocks flow from 1 to 2 until the predetermined pressure setting is reached at port 1 to lift the spring opposed ball from its seat, allowing flow from port 1 to port 2. Pressure at port 2 is directly additive to valve pressure setting. Flow from port 2 to port 1 is checked.

Features

- Spring ranges up to 5000 psi (350 bar)

- Positive stop prevents spring from over adjustment

- Adjustment screw cannot be backed out of the valve

- Adjustable under full pressure

- Fast response

- All external surfaces zinc-plated

- Hardened ball to ensure minimal wear and extend service life

DB06A-01

Pressure Relief, Direct Acting, Ball Type

Up to 4 gpm (15 l/min) • 5000 psi (350 bar)

Description

A screw-in cartridge, direct acting, ball type relief valve intended for use as pressure limiting device in hydraulic circuits requiring low internal leakage and fast response.

Operation

The DB06A blocks flow from 1 to 2 until the predetermined pressure setting is reached at port 1 to lift the spring opposed ball from its seat, allowing flow from port 1 to port 2. Pressure at port 2 is directly additive to valve pressure setting. Flow from port 2 to port 1 is checked.

Features

- Spring ranges up to 5000 psi (350 bar)

- Positive stop prevents spring from over adjustment

- Adjustment screw cannot be backed out of the valve

- Adjustable under full pressure

- Fast response

- All external surfaces zinc-plated

- Hardened ball to ensure minimal wear and extend service life

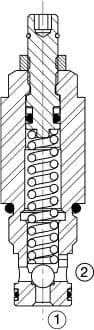

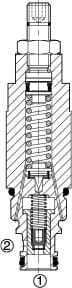

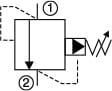

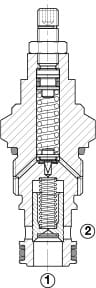

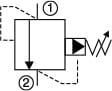

DB08A-01

Pressure Relief, Direct Acting, Poppet Type

10 gpm (38 l/min) • 6000 psi (420 bar)

Description

A screw-in cartridge, direct acting, poppet type relief valve intended for use as pressure limiting device in hydraulic circuits which require low internal leakage and fast response to pressure changes.

Operation

The DB08A blocks flow from port 1 to port 2 until the pressure setting is reached at port 1 to lift the spring opposed poppet from its seat, allowing flow from port 1 to port 2. Pressure at port 2 is directly additive to valve pressure setting. Flow from port 2 to port 1 is checked.

Features

- Spring ranges up to 6000 psi (420 bar)

- Positive stop prevents spring from over adjustment (options V,H)

- Adjustable under full pressure

- Stroke limiting device for enhanced safety

- Fast response

- All external surfaces zinc-plated

- Hardened poppet to ensure minimal wear and extend service life

- One piece body maximizes reliability and minimizes the effects of eccentricity

- Industry common cavity

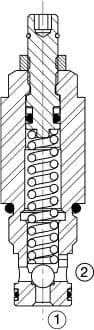

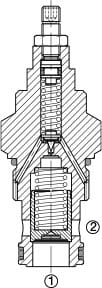

DB08P-01

Pressure Relief, Pilot Operated, Spool Type

16 gpm (60 l/min) • 5000 psi (350 bar)

Description

A screw-in cartridge, pilot operated (two stage), spool type relief valve intended for use as a pressure limiting device in hydraulic circuits requiring fast response and low pressure rise over a wide flow range.

Operation

The DB08P blocks flow from port 1 to port 2 until the predetermined pressure setting is reached at port 1 to lift the spring opposed pilot poppet off its seat, creating a low flow and a pressure drop across the orifice in the main spool. This allows the main spool to shift, opening port 1 to port 2. Pressure at port 2 is directly additive to valve pressure setting.

Features

- Spring ranges up to 5000 psi (350 bar)

- Positive stop prevents spring from over adjustment (options V,H)

- Adjustable under full pressure

- One-piece body maximizes reliability & minimizes the effects of eccentricity

- Low pressure rise over flow range

- Screen protected pilot orifice to enhance safety

- Fast response with excellent stability

- All external surfaces zinc-plated

- Hardened spool & pilot poppet to ensure minimal wear & extend service life

- Industry common cavity

DB10P-01

Pressure Relief, Pilot Operated, Spool Type

Up to 32 gpm (120 l/min) • 6000 psi (420 bar)

Description

A screw-in cartridge, pilot operated (two stage), spool type relief valve intended for use as a pressure limiting device in hydraulic circuits requiring fast response and low pressure rise over a wide flow range.

Operation

The DB10P blocks flow from port 1 to port 2 until the pressure setting is reached at port 1 to lift the pilot poppet creating a pressure drop across the main spool. This allows the main spool to shift, opening port 1 to port 2. Pressure at port 2 is directly additive to valve pressure setting.

Features

- Spring ranges up to 6000 psi (420 bar)

- Positive stop prevents spring from over adjustment (options V,H)

- Adjustable under full pressure

- One-piece body maximizes reliability and minimizes the effect of eccentricity

- Screen protected control orifice to enhance safety

- Fast response with excellent stability

- All external surfaces zinc-plated

- Hardened spool & pilot poppet to ensure minimal wear & extend service life

- Industry common cavity

DB12P-01

Pressure Relief, Pilot Operated, Spool Type

Up to 53 gpm (200 l/min) • 5000 psi (350 bar)

Description

A screw-in cartridge, pilot operated (two stage), spool type relief valve intended for use as pressure limiting device in hydraulic circuits requiring fast response and low pressure rise in a wide flow range.

Operation

The DB12P blocks flow from port 1 to port 2 until the pressure setting is reached at port 1 to lift the pilot poppet, creating a pressure drop across the main spool. This allows the main spool to shift, opening port 1 to port 2. Pressure at port 2 is directly additive to valve pressure setting.

Features

- Spring ranges up to 5000 psi (350 bar)

- Positive stop prevents spring from over adjustment (options V,H)

- Adjustable under full pressure

- One-piece body maximizes reliability and minimizes the effect of eccentricity

- Low pressure drop due to an optimized flow-path

- Screen protected pilot control orifice to enhance safety

- Fast response with excellent stability

- All external surfaces zinc-plated

- Hardened spool & pilot poppet to ensure minimal wear & extend service life

- Industry common cavity

DB16P-01

Pressure Relief, Pilot Operated, Spool Type

Up to 79 gpm (300 l/min) • 5000 psi (350 bar)

Description

A screw-in cartridge, pilot operated (two stage), spool type relief valve intended for use as pressure limiting device in hydraulic circuits requiring fast response and low pressure rise in a wide flow range.

Operation

The DB16P blocks flow from port 1 to port 2 until the pressure setting is reached at port 1 to lift the pilot poppet creating a pressure drop across the main spool. This allows the main spool to shift, opening port 1 to port 2. Pressure at port 2 is directly additive to valve pressure setting.

Features

- Spring ranges up to 5000 psi (350 bar)

- Positive stop prevents spring from over adjustment (options V,H)

- Adjustable under full pressure

- One-piece body maximizes reliability and minimizes the effect of eccentricity

- Low pressure drop due to an optimized flow-path

- Screen protected control orifice to enhance safety

- Fast response with excellent stability

- All external surfaces zinc-plated

- Hardened spool & pilot poppet to ensure minimal wear & extend service life

- Industry common cavity

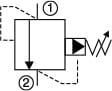

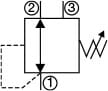

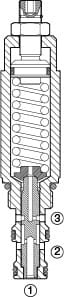

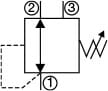

DR08-01

Pressure Reducing/Relieving, Direct Acting, Spool Type

4 gpm (15 l/min) • 6000 psi (420 bar)

Description

A screw-in cartridge, direct acting, spool type, pressure reducing/relieving valve with internal spring chamber drain, intended for use as a pressure regulating device. This valve maintains a constant secondary regulated/ reduced pressure regardless of pressure variations in the primary system. In addition to the reducing function, this valve also provides a relief function from the reduced pressure port to the tank port, if pressure in the secondary circuit exceeds the set pressure.

Operation

The DR08-01 allows bidirectional flow between port 2 and port 1 with the spring chamber drained through port 3. Once the pressure setting is reached at port 1, the spool shifts to restrict the flow at port 2, thereby regulating pressure at port 1. If pressure at port 1 exceeds the setting of the valve, the spool will shift further and relieve excess pressure through port 3. Any pressure at port 3 is directly additive to valve pressure.

Features

- Spring ranges up to 3000 psi (210 bar)

- Positive stop prevents spring from over adjustment (options V,H)

- Adjustable under full pressure

- Stroke limiting device for enhanced safety

- Fast response

- All external surfaces zinc-plated

- Hardened poppet to ensure minimal wear and extend service life

- Industry common cavity

DR10-01

Pressure Reducing/Relieving, Direct Acting, Spool Type

Up to 16 gpm (60 l/min) • 6000 psi (420 bar)

Description

A screw-in cartridge, direct acting, spool type, pressure reducing/relieving valve with internal spring chamber drain, intended for use as a pressure regulating device. This valve maintains a secondary regulated/reduced pressure regardless of pressure variations in the primary system. In addition to the reducing function, this valve also provides a relief function from the reduced pressure port to the tank port, if pressure in the secondary circuit exceeds the set pressure.

Operation

The DR10-01 allows bidirectional flow between port 2 and port 1 with the spring chamber drained through port 3. Once the pressure setting is reached at port 1, the spool shifts to restrict the flow at port 2, thereby regulating pressure at port 1. If pressure at port 1exceeds the setting of the valve, the spool will shift further and relieve excess pressure through port 3. Any pressure at port 3 is directly additive to valve pressure setting.

Features

- Spring ranges up to 1900 psi (131 bar)

- Positive stop prevents spring from over adjustment (options V,H)

- Adjustable under full pressure

- Stroke limiting device for enhanced safety

- Fast response

- All external surfaces zinc-plated

- Hardened poppet to ensure minimal wear and extend service life

- Industry common cavity

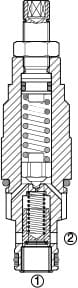

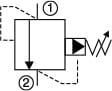

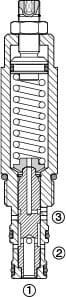

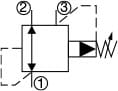

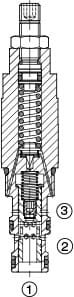

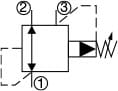

DR08P-01

Pressure Reducing/Relieving, Pilot Operated, Spool Type

16 gpm (60 l/min) • 5000 psi (350 bar)

Description

A screw-in cartridge, pilot operated, spool type, pressure reducing/relieving valve with internal pilot and internal spring chamber drain, intended for use as a pressure regulating device for secondary circuits. This valve maintains a secondary regulated/reduced pressure regardless of pressure variations in the primary system. In addition to the reducing function, this valve also provides a relief function from the reduced pressure port to the tank port, if pressure in the secondary circuit exceeds the set pressure.

Operation

The DR08P-01 allows bidirectional flow between port 2 and port 1 with the spring chamber drained through port 3. Once the pressure setting is reached at port 1, the spool shifts to restrict the flow at port 2, thereby regulating pressure at port 1. If pressure at port 1 exceeds the setting of the valve, the spool will shift further and relieve excess pressure through port 3. Any pressure at port 3 is directly additive to valve pressure setting.

Features

- Spring ranges up to 5000 psi ( 350 bar)

- Positive stop prevents spring from over adjustment (options V,H)

- Adjustable under full pressure

- One-piece body maximizes reliability and minimizes the effect of eccentricity

- Screen protected control orifice to enhance safety

- Fast response with excellent stability

- All external surfaces zinc-plated

- Hardened spool & pilot poppet to ensure minimal wear & extend service life

- Industry common cavity

DR10P-01

Pressure Reducing/Relieving, Pilot Operated, Spool Type

Up to 26 gpm (100 l/min) • 5000 psi (350 bar)

Description

A screw-in cartridge, pilot operated, spool type, pressure reducing/relieving valve with internal pilot and internal spring chamber drain, intended for use as a pressure regulating device for secondary circuits. This valve maintains a secondary regulated/reducted pressure regardless of pressure variations in the primary system. In addition to the reducing function, this valve also provides a relief function from the reduced pressure port to the tank port, if pressure in the secondary circuit exceeds the set pressure.

Operation

The DR10P-01 allows bidirectional flow between port 2 and port 1 with the spring chamber drained through port 3. Once the pressure setting is reached at port 1, the spool shifts to restrict the flow at port 2, thereby regulating pressure at port 1. If pressure at port 1exceeds the setting of the valve, the spool will shift further and relieve excess pressure through port 3. Any pressure at port 3 is additive to spring set pressure.

Features

- Spring ranges up to 5000 psi (350 bar)

- Positive stop prevents spring from over adjustment (options V,H)

- Adjustable under full pressure

- One-piece body maximizes reliability and minimizes the effect of eccentricity

- Screen protected control orifice to enhance safety

- Fast response with excellent stability

- All external surfaces zinc-plated

- Hardened spool & pilot poppet to ensure minimal wear & extend service life

- Industry common cavity