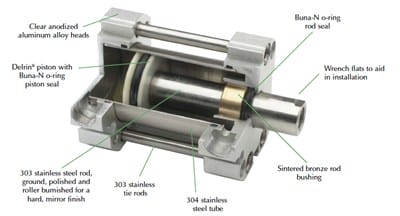

STAINLESS STEEL CYLINDER CONSTRUCTION

In the early 1950’s, Clippard introduced miniature pneumatic cylinders and valves to industry. No other manufacturer can boast of the same experience or knowledge of miniature components.

Air cylinders have always been an integral part of the Clippard Minimatic® line. Over the years Clippard has responded to requests from cylinder users to provide additional sizes of air cylinders and auxiliary support products. While competitively priced, these products maintain the Clippard standard for quality and reliability that has been the industry standard for many years.

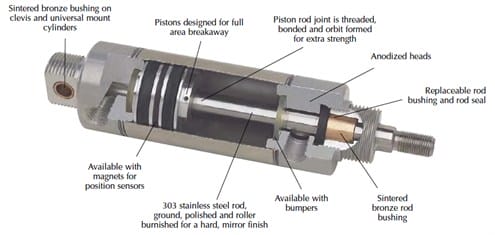

Features

- Polished I.D. 304 stainless steel tubes for low breakaway

- Precision rolled construction for a solid, leakproof cylinder at a reasonable price

- Machined aluminum heads are clear anodized for extra protection against corrosion

- Cylinder heads are machined from one side for better concentricity

- Sintered bronze rod bushing

- Sintered bronze clevis bushing on all clevis and universal mount cylinders

- Rods are threaded, bonded and orbit formed to pistons

- Replaceable rod seal on 28 through 48 series

- Ground, polished and roller burnished 303 stainless rods provide a smoother rod finish that protects rod seals, giving longer life

- Full piston area breakaway to assure full power from the beginning of each stroke

- Buna-N “U”-cup piston seals for full power, low friction and trouble-free performance

- Buna-N “U”-cup rod seals for leakproof operation

- Temperature range: 32 to 230°F

- Maximum pressure: 250 psig

Options

Fluorocarbon Seals -V

This option is used in applications where chemical resistance,

compatibility and temperature become an issue. Temperature

ranges: -20 up to 400°F.

Bumpers -B

Internal polyurethane bumpers are supplied for applications where the cylinder is cycled with a light load and/or high speeds. The elastic bumpers reduce noise and shock to the load. Use of this option may add to the overall length of the cylinder. See specific cylinder listings on the following pages for availability and details of the overall length added. Maximum temperature 200°F.

Cushions -C

(Front Cushion Only) -F

(Rear Cushion Only) -R

Clippard’s cushion cylinders offer an adjustable cushion to slow the cylinder near the end of the stroke to reduce impact and prolong cylinder life. Our adjustment needle is held captive to prevent the needle from blowing out. The cushion can be adjusted to have a dead stop 1/2″ from end of stroke or adjusted to have virtually no effect on the action of the cylinder.

Side Ported -S

Side ported rear heads are sometimes needed when the standard cylinder has the rear port out the back. This option changes the design of the rear head so the rear port is located on the side of the cylinder. Overall length of cylinder changes with this option.

No Rod Threads -N

Rods are provided with no threads when this option is ordered.

Heavy Spring -H

In single acting, reverse acting or spring bias cylinders the standard spring force can be changed by ordering the -H option.

Magnetic Piston -M

Clippard stainless steel pneumatic cylinders that are equipped with an internal magnet can be used with the Reed Switch and GMR Sensor. By accurately sensing the magnetic field of the piston when it passes beneath the sensor, the position of the rod piston is determined, and the feedback signal is created. Use of this option may add to the overall length of the cylinder. See specific cylinder listings on the following pages for availability and details of the overall length adder.

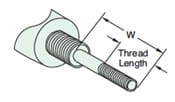

Rod Extensions

For a special rod extension on single- or double-acting cylinders, indicate desired “W” when rod is at rest (retracted) with no pressure to either port. For reverse acting cylinders, indicate “W” when rod is at rest (extended) with no pressure to either port.

W = _____ Thread Length = ______

Rod Wipers -W

Rod Wipers are added to cylinders in applications where a liquid wash could dry out the rod seals of a double acting cylinder.

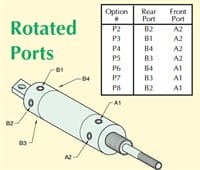

Rotated Ports

This option is used in applications where ports need to be rotated to accommodate a specific space requirement or port orientation for the fittings and tube attachments. The diagram explains the options and orientation of the ports. See the specific cylinder to find availability of these options.

Stroke Lengths

Corrosion-Resistant Cylinders

Clippard’s line of Delrin® head stainless steel cylinders offer all of the advantages of Clippard’s high quality, reliable stainless steel cylinders, with the added benefit of corrosion resistance. These cylinders are ideal for applications where equipment cleanliness is critical, since they can be put to work in harsh environments requiring frequent use of hot water and chemicals.

Clippard corrosion-resistant cylinders are available in bore sizes ranging from 5/8″ to 1 1/2″. Standard stroke lengths range from 1/2″ to 6″. The cylinder tubes and rods are made of stainless steel. The rods are ground, polished, and roller burnished. Buna-N® seals are standard with a Fluorocarbon option available for compatibility. A magnetic piston is also optional.

These lightweight cylinders have a temperature range from 32 to 180°F, and have a pressure rating of 150 psig (air). A variety of mounting styles are available.

Delrin® is a registered trademark of E.I. DuPont Co.

Features

- Delrin® heads with a positive double seal

- Available with magnetic pistons

- 303 stainless steel ground, polished and roller burnished piston rods

- Precision rolled construction for a solid leak-proof cylinder

- Buna-N seals (Fluorocarbon optional for compatibility only)

- 304 stainless steel tube

- Pressure Range: 0 to 150 psig

- Temperature range: 32 to 180°F

- Optional stainless steel mounting nuts

- Aluminum alloy pistons, optional Delrin® pistons available; consult factory

Air Force One® Compact Cylinders

Clippard Instrument Laboratory, Inc. Air Force One compact cyl in ders are available in double acting, spring return, spring extend and double rod models. GMR sensors and magnetic piston versions are also available.

The AFO cylinder features include a stainless steel tube and roller burnished piston rod. This means longer rod and piston seal life. For corrosive environments, where dirt and abra sives may be ingested, and cause seals to wear fast er than normally expected, the AFO of fers the ben e fit of tie rod construction. This enables seals to be re placed, rather than replacing the entire cyl in der. The non-corrosive construction of the AFO cylinder body is reliable in abrasive environments, able to withstand the tough est conditions.

The various mounting configurations available in the AFO cylinders assure freedom to interchange with most cylinders on the market. This means most sys tems can be upgraded to in clude quality AFO cylinders.

Features

- Oil impregnated sintered bronze rod bushing

- Available with magnetic pistons

- 303 stainless steel ground, polished and roller burnished piston rods

- Double acting, spring return, spring extend & double rod cylinders

- 304 stainless steel tube

- Temperature range: 30 to 180° F

- Anodized aluminum heads

- Air pressure rating to 250 psig

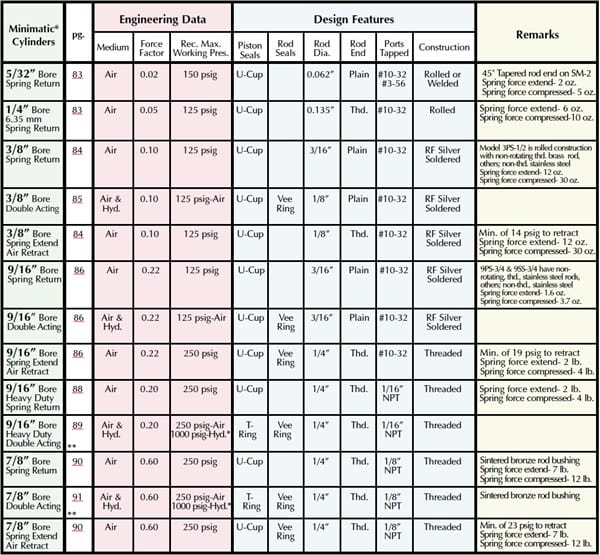

Minimatic® Cylinders

Clippard offers more types of miniature pneumatic cylinders for the designer’s convenience, including: spring return, spring extend, air retract, double-acting and double rod models. From subminiature (5/32″ bore) to heavy-duty (7/8″ bore), the extensive Clippard line provides a wide selection of bore sizes to suit any application requirement. An even wider range of strokes are available in the complete Clippard line of miniature cylinders, in stroke sizes ranging from 1/4″ to 20″.

- Rods are threaded and bonded to piston

- The original miniature pneumatic cylinder

- Buna-N “U”-cup rod seals for smooth leakproof operation

- Buna-N “U”-cup piston seals for full power, low friction and trouble-free performance

- 100% tested

- Pneumatic & hydraulic performance

- Sturdy, compact and long life

- Temperature range: 30 to 180°Fv

The Clippard line offers numerous choices in the mounting of Clippard Minimatic® cylinders. The cylinders are provided in several types of mounting styles including plain end, stud mount, block mount, and clevis mount (male and female). In addition, a complementary line of mounting hardware, including brackets, male and female clevises and Clippard’s Minimatic® super structures are available for almost any application.

Clippard cylinders are of original design, pioneered by the world’s most experienced manufacturer of miniature pneumatic equipment. They are of the finest OEM quality, fully tested for outstanding performance and long life. Special steps in manufacture insure the high quality of Clippard cylinders. These include: ground, polished and roller burnished rods to protect seals and provide smooth action; tube I.D. precision through “ballizing” with carbide precision balls; high precision screw machine parts manufacture, based on concentric design that lends itself to close tolerance machining. The reputation Clippard has earned in the field is a result of our policy to test every cylinder (100%) we manufacture.