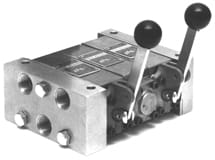

Typical Section

Typical 3-Section Assembly

VACUUM TO 250 PSI

(Subject to Pressure Limitations on Certain Models)

The Series B stack valve consists of individual sections sandwiched between two end plates, the stack being held together with three tie bolts. Individual sections shown in the model chart, are available with a variety of actuators. A stack assembly can have sections with an assortment of actuators.

Pressure and exhaust connections are 1/2˝ NPTF on both the 1/4˝ and 3/8˝ sizes. They come in through threaded port holes on one end plate and are manifolded to all sections. Cylinder connections come out threaded port holes, 1/4˝ or 3/8˝ NPTF in the side of each section. The stack can be turned with all cylinder port holes up or with all port holes down.

RATINGS. Valve bodies are rated for vacuum or compressed air up to 250 PSI. Not recommended for liquids. Solenoid sections are rated 50 to 150 PSI for spring centered and spring return models, 25 to 150 PSI for others. Higher or lower pressure can be handled by supplying external pilot pressure to each solenoid actuator.

Flow capacity is the same for 1/4˝ or 3/8˝ sizes. Only the cylinder connection size is different. Capacity is sufficient to operate air cylinders up to 3˝ bore at normal speeds, and larger cylinders at reduced speeds. Cylinder speed can be controlled with flow control valves installed in cylinder lines.

| Type | Model 1/4˝ NPTF Threads | Model 3/8˝ NPTF Threads | Description |

| Single solenoid | EBSO2 | EBSO3 | 2-position, spring returned spool |

| Single solenoid | EBSR2 | EBSR3 | 2-position, pilot returned spool |

| Double solenoid | EBSS2 | EBSS3 | 2-position spool, no springs |

| Double solenoid | EBSY2 | EBSY3 | 3-pos., spring cent., closed center |

| Manual lever | BHE2 | BHE3 | 2-position, friction positioned spool |

| Manual lever | BHO2 | BHO3 | 2-position, spring returned spool |

| Manual lever | BHY2 | BHY3 | 3-pos., spring cent., closed center |

| Manual lever | BHD2 | BHD3 | 3-position, detented, closed center |

| Manual lever | BHD2Q | BHD3Q | 2-position, detented spool |

| Palm button | BKE2 | BKE3 | 2-position, friction positioned spool |

| Palm button | BKO2 | BKO3 | 2-position, spring returned spool |

| Palm button | BKY2 | BKY3 | 3-pos., spr. cent., closed center |

| Palm button | BKD2 | BKD3 | 3-position detented, closed center |

| Palm button | BKR2 | BKR3 | 2-position, pilot returned spool |

| Palm button | BKD2Q | RKD3Q | 2-position, detented spool |

| Cam operated | BCO2 | BCO3 | 2-position, spring returned spool |

| Cam operated | BCR2 | BCR3 | 2-position, pilot returned spool |

| Pilot operated | BRR2 | BRR3 | 2-position, double piloted spool |

| Pilot operated | BRO2 | BRO3 | 2-position, spring returned spool |

| Pilot operated | BRY2 | BRY3 | 3-pos., spr. cent., closed center |

| Button bleed | BD2 | BD3 | 2-position, double bleed |

| Button bleed | BDY2 | BDY3 | 3-pos. spring cent., closed center |

| Button bleed | BDO2 | BDO3 | 2-position, spring returned spool |

VOLTAGES. Standard voltages for solenoid sections are 120 or 240V, 60 Hz., and 12 or 24 VDC. Contact our office for other voltages.

MATERIALS OF CONSTRUCTION. Vacuum cast aluminum bodies. Aluminum spools with glass-hard surface finish.

How to Order

Model numbers in chart are for individual 1/4˝ or 3/8˝ sections with closed center spools. Ported end plate can be mounted on either end. Actuators can all extend the same direction or in opposite directions. Assemblies can have all cylinder ports on top or all coming out the bottom.

Your order should specify the number of sections and model number of each starting at the end with threaded inlet and exhaust ports. Your valve will be assembled with tie rods and any necessary spacer plates, and shipped ready to install. In clear text give any special instructions for assembly.

Assembling in Your Plant

Order individual sections and all necessary end plates and spacer plates. Place all sections side by side in any desired order. Place a threaded end plate PEP-4 on one end (either end) and a blank end plate BEP-4 on the other end. Place a BOS-4 1/8˝ spacer on one end of the stack (depending on which way the sections are turned), to support O-rings. Add spacer plate PS-4 or XPS-4 as required.

Cut tie rods to length from all-thread steel rod. Allow 1-5/16˝ for each valve section, 1˝ for threaded end plate, 5/8˝ for blank end plate, 1/8˝ for BOS-4 spacer. For adjacent optional classic solenoid sections allow 5/16˝ for each PS-4 spacer, or 1/2˝ for each XPS-4 spacer if explosion proof solenoids are used. Threaded rods can be purchased locally or are available from the factory in tie rod kits.

Actuators are normally mounted on end, but can be mounted on opposite end of section. Take off actuator and end cap and reverse their positions. NOTE: on manual lever, spring centered sections, the lever must be removed before spool can be pulled out.

Accessories Required for Valve Assembly

PEP-4. End plate, 1˝ thick with 1/2˝ NPTF threaded inlet and exhaust ports. Includes three O-ring seals.

BEP-4. Blank end plate, 5/8˝ thick with three O-ring seals.

BOS-4. 1/8˝ spacer with three holes. Used between an end plate and adjacent section to support O-rings. One required on each stack.

PS-4. Spacer plate, 5/16˝ thick with three O-ring seals. For use between two adjacent solenoid sections when using optional classic solenoid or to space hand valves apart.

XPS-4. Spacer plate, 1/2˝ thick with three O-ring seals. For use between two adjacent solenoid sections with optional classic explosion proof operators or to space hand valves apart.

TRK-18. Tie rod kit containing three 18˝ long tie rods. Cut lengths to suit. Includes six nuts and six lockwashers.

TRK-36. Tie rod kit containing three 36˝ long tie rods. Cut lengths to suit. Includes 12 nuts and 12 lockwashers.

BRKV-3MP. Replacement seal kit fits any Series B valve section. Includes six Viton® body O-Rings, three buna-N section O-rings, and two end cap gaskets.