Data Sheet 21: U.S. Customary Units Compared to ISO International Standard Units

Preliminary work was started on an international system of units prior to 1954, and some European countries have adopted their own version of a metric system which could be used internationally. However, there are many duplicate metric units which could be used for the same function. At this writing the basic units which we believe will be adopted are shown in the second column of the chart, and will form the SI (International Standard) set of units which will eventually be used all over the world. Some of the units (like the meter) are unhandy for fluid power use and a variation (like the centimeter) may be used instead. These are shown in the third column of the chart. Correct abbreviations for each unit are shown in the table under the chart. There is still controversy over the use of the “bar” for pressure.

| Function | Basic SI Unit | Suggested Variation, Fluid Power | Other Metric Equivalents | Conversion To/ From U.S. Units |

| Length | m | cm | 1 m = 10 dm = 100 cm = 1,000 mm | 1 m = 39.37 in; or, 1 in = 2.54 cm |

| Area | m2 | cm2 | 1 m2 = 100 dm2 = 10,000 cm2 | 1 m2 = 1,550 in2 = 10.76 ft2 |

| Volume | m3 | dm3 | 1 m3 = 1,000 dm3 = 1,000 liters | 1 m3 = 61,023 in3 = 35.3 ft3 |

| Accel. of Gravity | m/s2 | Same | Actual value = 9.806 m/s2 | Actual value = 32.17 ft/s2 |

| Mass | kg | Same | 1 kg = 9.807N (joules/meter) | 1 kg = 2.2046 lbs (mass) = 70.92 poundals |

| Force (Weight) | N | Same | 1N = 0.102 kg = 1 × 105 dynes | 1N = 0.225 lbs |

| Torque | Nm | Same | – – – – | 1 Nm = 8.85 in. lb = 0.74 ft. lb |

| Stress | N/m2 | Same | 1 N/m2 = 1 × 10-5 bar | 1 N/m2 = 1.45 × 10-4 lbs/in2 = 0.021 lbs/ft2 |

| Pressure (Fluid) | N/m2 | bar | 1 bar = 100,000 N/m2 | 1 bar = 14.5 PSI; or, 1 PSI = 0.069 bar |

| Power | w | kw | 1 kw = 1,000w | 1 kw = 1.34 HP; or, 1 HP = 746w = 0.746 kw |

| Velocity | m/s | dm/min | 1 m/s = 600 dm/min | 1 dm/min = 3.937 in/min |

| cm = centimeter | in. lb = inch pound | min = minute | ||

| dm = decimeter | in/min = inches per minute | m/s = meters per second | ||

| dm/min = decimeters per minute | kg = kilogram | m/s2 = meters per sec. per sec. | ||

| ft = foot | kw = kilowatt | N = newton | ||

| ft. lb = foot pound | lb = pound | Nm = newton meters | ||

| ft/s2 = feet per second per second | lb/in2 = pound per square inch | N/m2 = newtons per square meter | ||

| g = gram | lb/ft2 = pounds per square foot | PSI = pounds per square inch | ||

| HP = horsepower | m = meter | s = second | ||

| in = inch | mm = millimeter | w = watt |

| Familiar Formula in Customary U.S. Units | Same Formula in the New SI Standard Units | |

| Torque, Power, and Speed Relations in Hydraulic Pumps & Motors | ||

| T = HP × 5,252 ÷ RPM | T = kw × 9,543 ÷ RPM | |

| HP = T × RPM ÷ 5,252 | kw = T × RPM ÷ 9,543 | |

| RPM = HP × 5,252 ÷ T | RPM = kw × 9,543 ÷ T | |

| T is torque in foot lbs. | T is torque in Nm (newton meters) | |

| RPM is speed in revolutions per minute | RPM is speed in revolutions per minute | |

| HP is horsepower (33,000 ft. lbs/min.) | kw is power in kilowatts | |

| Hydraulic Power Flowing in the System | ||

| HP = PSI × GPM ÷ 1,714 | Kw = Bars × dm3 ÷ min ÷ 600 | |

| HP is horsepower (33,000 ft. lbs. per min.) | Kw is system power in kilowatts | |

| PSI is gauge pressure, lbs. per square inch | Bars is system pressure | |

| GPM is flow in gallons per minute | dm3/min is flow in cubic decimeters per minute | |

| Force Developed by Air or Hydraulic Cylinder | ||

| T = A × PSI | N = A × Bars × 10 | |

| T is force or thrust, in pounds | N is cylinder force or thrust in newtons | |

| A is piston area in square inches | A is piston area in square centimeters | |

| PSI is gauge pressure, lbs. per sq. in. | Bars is gauge pressure | |

| Travel Speed of a Hydraulic Cylinder | ||

| S = V ÷ A | S = V ÷ 6A | |

| S is travel speed in inches per minute | S is travel speed in meters per second | |

| V is volume of oil into cylinder, cu. ins. per min. | V is oil flow in cubic decimeters per minute | |

| A is piston area in square inches | A is piston area in square centimeters | |

| Barlow’s Formula for Calculating Burst Pressure of Tubing and Pipe | ||

| P = 2t × S ÷ O | P = 2t × S ÷ O | |

| P is burst pressure in PSI | P is burst pressure in bars | |

| t is wall thickness of pipe in inches | t is wall thickness of pipe in millimeters | |

| S is tensile strength of pipe material in PSI | S is tensile strength of pipe material in bars | |

| O is outside diameter of pipe in inches | O is outside diameter of pipe in millimeters | |

| Velocity of Oil flow in Hydraulic Lines | ||

| V = GPM × 0.3208 ÷ A | V = dm3/min ÷ 6A | |

| V is velocity in feet per second | V is oil velocity in meters per second | |

| GPM is oil flow in gallons per minute | dm3/min is flow in cubic decimeters per second | |

| A is inside area of pipe in square inches | A is inside area of pipe in square centimeters | |

| Recommended Maximum Oil Velocity in Hydraulic Lines | ||

| Pump suction lines – 2 to 4 per sec. | Pump suction lines – 0.6 to 1.2 m/s (meters/sec) | |

| Pressure lines up to 500 PSI – 10 to 15 ft/sec. | Pressure lines up to 35 bar – 3.0 to 4.5 m/s | |

| Pressure lines 500 to 3,000 PSI – 15 to 20 ft/sec. | Pressure lines 35 to 200 bar – 4.5 to 6.0 m/s | |

| Pressure lines over 3,000 PSI – 25 ft/sec. | Pressure lines over 200 bar – 7.5 m/s | |

| Oil lines in air/oil system – 4 feet per sec. | Oil lines in air/oil system – 1.2 m/s | |

| See Design Data Sheet 25 for many other conversions between U.S. customary and ISO units | ||

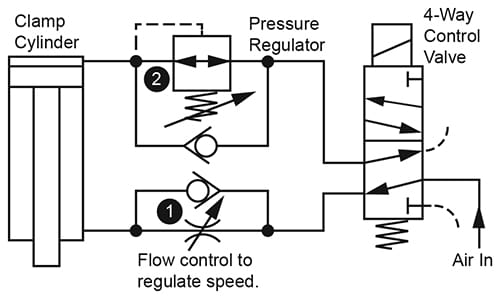

CLAMPING DELICATE PARTS

When an air cylinder is used for clamping delicate parts, the parts may be distorted, crushed, or suffer other damage for either or both of two possible reasons:

- Too high a travel speed of the clamp cylinder may cause damage from impact, especially when the clamp is carrying a significant weight (mass) attached to its piston rod. This type of damage can be avoided by using a speed control and reducing travel speed. A flow control valve, 1, connected in a meter-out circuit will solve this problem.

- Even though speed is reduced, the part can be crushed from too much steady force after the clamp has closed. When the clamp stalls against the part to be clamped, it will, if given a second or so, come up to full force developed by system PSI working against full piston area. A speed control system, by itself, cannot prevent full force from being exerted against the clamped part. To reduce the force, a pressure regulator, 2, should be installed in the air line to the clamp, and by-passed with a check valve so the clamp can be released fast and retracted under full pressure.

To adjust this circuit, first set the pressure regulator to a pressure which will not damage the part when clamping force is constantly applied. Then adjust the speed control to a speed which will not produce a damaging impact.

Both a speed and a pressure control may be required to avoid a damaging a delicate part which is being clamped.

© 1990 by Womack Machine Supply Co. This company assumes no liability for errors in data nor in safe and/or satisfactory operation of equipment designed from this information.