Data Sheet 32: Pressure Rating of Steel Cylinder Tubing

The chart on this page shows the fluid pressure rating of mild steel tubing used for cylinder barrels. Tubing inside diameter (bore) is shown in the first column, and wall thickness along the top of the chart.

The chart includes an ample safety factor to take care of variations in composition or wall thickness of production tubing, pressure spikes generated in the hydraulic system, and metal fatigue caused by high cycle rates. More complete information is given on the opposite side of this sheet.

Safe Working Pressure

The calculation of safe working pressure on steel tubing used for construction of hydraulic cylinders is not an exact science because there are possible variations in the tubing material plus many other variables such as these:

- SAE grade and hardness of he tubing steel.

- SAE grade and hardness of he tubing steel.

- Whether the tubing steel is ductile or brittle.

- Whether the cylinder will be constructed with “floating” ends or with confined (welded) ends.

- Ratio of wall thickness to inside diameter of tubing.

- Operating temperature (if extremely high).

- Cycle rate. (High cycle rate tends to fatigue tubing).

Formula for Calculating Pressure Rating

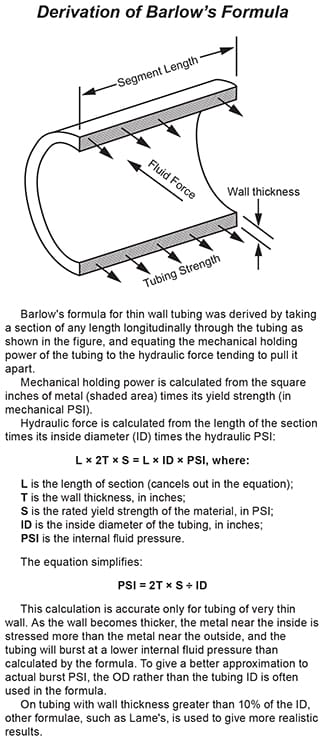

Several formula may be used to calculate wall thickness for a desired hydraulic working pressure, but two of them seem to be used more than the others for ductile steel tubing. Lame’s formula is used for thick wall tubing. This includes tubing with a wall thickness greater than 10% of its inside diameter. If the wall thickness is less than 10% of the I.D., the tubing is considered as “thin wall”, and Barlow’s formula gives more accurate results. Most of the tubing used to plumb a hydraulic system is “thin wall”, and its pressure rating can be calculated with the same formula given here for cylinder barrel thin wall tubing.

Material for Cylinder Barrels

The most common material for hydraulic cylinder barrels seems to be low carbon steel, such as SAE 1020, finish annealed, or plain low carbon cold drawn seamless steel tubing, with a hardness of about 84 Rockwell B, and having a tensile yield point of 60,000 PSI (mechanical). This material has been used to build cylinders rated at 6,000 PSI working and up to 5-inch bore. To build cylinders with higher pressure rating or larger bore, a ductile steel with higher yield point should be used. Cast iron (a brittle material) should never be used for pressure ratings over 2,000 PSI regardless of wall thickness.

Working Pressure of Steel Tubing for Cylinder Barrels

| Bore (Inside Diameter | Wall Thick., 1/8˝ 0.125 | Wall Thick., 3/16˝ 0.1875 | Wall Thick., 1/4˝ 0.250 | Wall Thick., 3/8˝ 0.375 | Wall Thick., 1/2˝ 0.500 | Wall Thick., 5/8˝ 0.625 | Wall Thick., 3/4˝ 0.750 | Wall Thick., 7/8˝ 0.875 | Wall Thick., 1˝ 1.000 | Wall Thick., 1-1/4˝ 1.250 | Wall Thick., 1-1/2˝ 1.500 | Wall Thick., 1-3/4˝ 1.750 |

| 1.50 | 1600 | 2195 | 2800 | 3845 | 4705 | – – – – | – – – – | – – – – | – – – – | – – – – | – – – – | – – – – |

| 1.75 | 1380 | 2045 | 2460 | 3425 | 4235 | – – – – | – – – – | – – – – | – – – – | – – – – | – – – – | – – – – |

| 2.00 | 1250 | 1790 | 2350 | 3080 | 3845 | 4505 | – – – – | – – – – | – – – – | – – – – | – – – – | – – – – |

| 2.25 | 1110 | 1510 | 2100 | 2800 | 3520 | 4150 | – – – – | – – – – | – – – – | – – – – | – – – – | – – – – |

| 2.50 | 1000 | 1445 | 1905 | 2565 | 3245 | 3935 | 4380 | – – – – | – – – – | – – – – | – – – – | – – – – |

| 2.75 | 910 | 1365 | 1740 | 2545 | 3005 | 3580 | 4095 | – – – – | – – – – | – – – – | – – – – | – – – – |

| 3.00 | 835 | 1250 | 1600 | 2350 | 2800 | 3350 | 3845 | 4295 | – – – – | – – – – | – – – – | – – – – |

| 3.25 | 770 | 1155 | 1480 | 2175 | 2620 | 3110 | 3620 | 4060 | – – – – | – – – – | – – – – | – – – – |

| 3.50 | 715 | 1070 | 1380 | 2035 | 2460 | 2935 | 3435 | 3845 | 4235 | – – – – | – – – – | – – – – |

| 4.00 | 625 | 940 | 1250 | 1790 | 2350 | 2655 | 3080 | 3480 | 3845 | – – – – | – – – – | – – – – |

| 4.50 | 555 | 835 | 1110 | 1600 | 2100 | 2405 | 2800 | 3170 | 3520 | 4150 | – – – – | – – – – |

| 5.00 | 500 | 750 | 1000 | 1445 | 1905 | 2195 | 2565 | 2915 | 3245 | 3845 | – – – – | – – – – |

| 5.50 | 455 | 680 | 910 | 1365 | 1740 | 2495 | 2365 | 2695 | 3005 | 3580 | 4100 | – – – – |

| 6.00 | 415 | 625 | 835 | 1250 | 1600 | 1980 | 2195 | 2505 | 2800 | 3350 | 3845 | – – – – |

| 6.50 | 385 | 575 | 770 | 1155 | 1480 | 1835 | 2175 | 2340 | 2620 | 3145 | 3625 | 4060 |

| 7.00 | 355 | 535 | 715 | 1070 | 1380 | 1710 | 2030 | 2195 | 2460 | 2960 | 3425 | 3845 |

| 7.50 | 335 | 500 | 665 | 1000 | 1335 | 1600 | 1905 | 2065 | 2320 | 2800 | 3245 | 3655 |

| 8.00 | 310 | 470 | 625 | 935 | 1250 | 1500 | 1790 | 2070 | 2195 | 2655 | 3080 | 3480 |

| 8.50 | 295 | 440 | 590 | 880 | 1175 | 1420 | 1690 | 1955 | 2080 | 2525 | 2935 | 3320 |

| 9.00 | 275 | 415 | 555 | 839 | 1110 | 1345 | 1600 | 1855 | 2100 | 2405 | 2800 | 3170 |

| 9.50 | 265 | 395 | 525 | 790 | 1050 | 1395 | 1520 | 1760 | 1995 | 2295 | 2675 | 3040 |

| 10.0 | 250 | 375 | 500 | 750 | 1000 | 1250 | 1445 | 1675 | 1905 | 2195 | 2565 | 2915 |

| 10.5 | 240 | 355 | 475 | 715 | 950 | 1190 | 1380 | 1600 | 1835 | 2245 | 2460 | 2800 |

| 11.0 | 225 | 340 | 455 | 680 | 910 | 1135 | 1365 | 1415 | 1740 | 2145 | 2365 | 2695 |

| 11.5 | 215 | 325 | 435 | 650 | 870 | 1085 | 1305 | 1465 | 1665 | 2060 | 2275 | 2595 |

| 12.0 | 210 | 310 | 415 | 625 | 835 | 1040 | 1250 | 1410 | 1600 | 1980 | 2195 | 2505 |

| 12.5 | 200 | 300 | 400 | 600 | 800 | 1000 | 1200 | 1355 | 1540 | 1905 | 2120 | 2420 |

| 13.0 | 190 | 290 | 385 | 575 | 770 | 960 | 1155 | 1345 | 1480 | 1835 | 2175 | 2340 |

| 13.5 | 185 | 275 | 370 | 555 | 740 | 925 | 1110 | 1295 | 1430 | 1770 | 2145 | 2265 |

| 14.0 | 180 | 270 | 355 | 535 | 715 | 895 | 1070 | 1250 | 1380 | 1710 | 2035 | 2195 |

| Pressures to the left of the shaded area were calculated by Barlow’s formula. Those to the right of shaded area by Lame’s formula. Pressures in shaded area are average values from calculations by both formula. | ||||||||||||

Explanation of Chart

Working Pressure: The chart is based on a mechanical stress, S, of 10,000 PSI in the tubing material. This is fairly conservative, and gives a safety factor of 5:1 for steel tubing rated for 50,000 PSI yield, or a safety factor of 6:1 for steel tubing rated for 60,000 PSI yield strength. While it may, on some applications, be permissible to use a lower safety factor, under no circumstances would we recommend a safety factor less than 2.5 because of pressure spikes in the hydraulic system, and variations in composition or wall thickness of the tubing. Using a safety factor of 2.5, tubing of dimensions shown in the chart could be used at pressures about twice those shown.

Thin Wall Tubing. Fluid pressure values to the left of the shaded area were calculated by Barlow’s formula as explained in the box on this page. These are for tubing sizes where wall thickness is less than 7% of the tubing I.D.

Thick Wall Tubing. Fluid pressure values to the right of the shaded area were calculated by Lame’s formula:

PSI = S × (OR² − IR² ) + (OR² + IR² ), where:

PSI is fluid pressure;

S is rated yield strength of the material, in PSI;

OR is the outside radius, in inches;

IR is the inside radius, in inches.

This area of the chart includes tubing with wall thickness greater than 10% of the tubing I.D. All areas of the chart are based on the design stress noted above, 10,000 PSI (mechanical), also including the safety factors noted above.

Intermediate Wall Thickness. The shaded area of the chart on the opposite side of this sheet includes tubing with wall thickness between 7% and 10% of tubing I.D. In an attempt to obtain more realistic results, pressure values were calculated with both the thin wall and thick wall formula and the two results were averaged.

Tubing Sizes Not Shown in Chart

The formula and general rules given above may be used to determine working pressure of other tubing sizes, or tubing of other material which is ductile, if its tensile yield strength is known.

© 1990 by Womack Machine Supply Co. This company assumes no liability for errors in data nor in safe and/or satisfactory operation of equipment designed from this information.